Vinegar is the sour liquid obtained by naturally fermenting the juice of any fruits, cereals, or sugar substances.

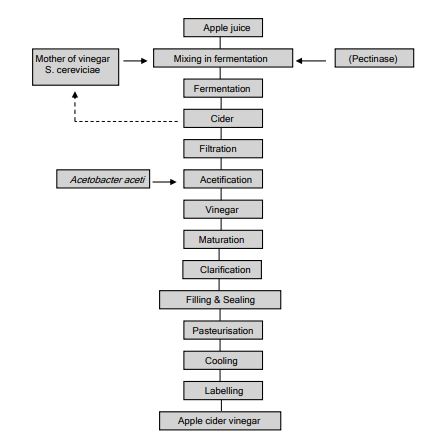

Apple vinegar is produced by alcoholic fermentation followed by acetous bacterial oxidation of apple juice. Apple vinegar should contain between 5 and 12% acetic acid. Apple cider vinegar is produced from apple juice or diluted concentrate. The process consists of two fermentation processes, followed by a clarification process.

Process description

Fermentation of apple juice

Fermentation is basically the addition of specific micro-organisms to food to convert the carbohydrate components to acids or alcohol, coupled with the production of carbon dioxide. For the production of apple cider vinegar, two different fermentation processes are used. In the first process, apple juice is converted into apple beer (cider) by yeast that converts the sugars (carbohydrates) into alcohol and carbon dioxide.

The carbon dioxide escapes. The beer then undergoes a second fermentation under different conditions, by a different agent, to produce the vinegar. The first fermentation process takes place in large fermentation tanks or in small wooden barrels, depending on the scale of the processing plant. The tanks are insulated to ensure that the optimum temperature is maintained throughout the entire incubation period. Coneshape tanks will ease the removal of the product.

The apple juice, together with some of the beer from a previous batch (the mother of vinegar) or pure yeast cultures (vinegar plant) containing the desired yeast colonies (Saccharomyces cerevisiae), is added to the tank. Natural yeast fermentation is allowed to take place. Initially, some air (oxygen) is required to stimulate yeast growth and increase cell mass. Aeration is achieved by occasional stirring. But conditions soon become anaerobic to favour the actual yeast fermentation of sugar to alcohol. Pectinase enzymes may be added to prevent haze formation during further processing. Fermentation is a slow process and the reaction will stop naturally when the alcohol content is 5 to 10%. About half of the beer is drawn off and fresh product is added to undergo fermentation.

Fermentation tanks. (Image Source: westons-cider.co.za)

Filtration of apple beer

The fermented product is filtered to rid the solution of any suspended matter. Cloth filters with mechanical presses are commonly used.

Acetification of apple cider to produce vinegar

Acetification is basically the second fermentation process in the making of apple cider vinegar. It involves the inoculation of the beer (cider) with a specific bacterial culture (Acetobacter aceti subsp aceti) that oxidises ethanol to acetic acid, and thereby gives rise to vinegar. This process is promoted by highly aerobic conditions that are created in a vinegar generator.

Various designs are available, but basically a vinegar generator consists of large tanks packed with wood shavings to provide a large aerobic surface area. The cider is mixed with 100 to 300 ppm of the inoculum and trickled through the wood shavings while air is blown up through the product. The temperature is kept between 28 and 36 °C, and the vinegar is removed from the generator when its acetic acid concentration reaches 4%. This may take 1 to 15 days, depending on conditions.

Different brands of apple cider vinegar. (Image Source: media4.popsugar-assets.com)

Maturation of apple cider vinegar

The resulting raw vinegar is filtered and pumped to storage vats where it matures for several months under cool conditions. The product is allowed to stand for 30 to 365 days to ensure that the taste of the final product is in accordance with requirements.

Clarification of apple cider vinegar

The mature vinegar contains suspended matter that causes undesirable opaqueness of the product. The appearance of the vinegar is improved by clarification, which is achieved by filters or centrifuges. A centrifugal clarifier consists of a stack of conical disks kept apart by strips of metal to form separation channels. The vinegar is fed into a central inlet tube into the bowl and enters the channels at the outer edge at the bottom of the clarifier. It moves through the conical disks and then through an outlet at the top that is separate from the inlet tube.

The centrifugal force separates the solids from the vinegar. The solids are collected at the bottom and discarded. A rotary vacuum filter can also be used in a continuous clarification process. A filter cloth is attached to the surface of a perforated drum to which a vacuum can be applied. The drum rotates slowly and a pre-coat of filter aid is applied. The vinegar is sprayed on the outside of the drum, and is sucked through the filter aid and cloth to the inside.

Filling and sealing of apple cider vinegar

Vinegar is packed in plastic bottles with press-seal caps. The packaging materials should have high acid tolerance. The bottles are filled by the injection of the vinegar into the bottles with nozzles. A headspace (space between the product and the seal) is necessary to allow for the expansion of the product during the heating process. The containers are then hermetically sealed. A hermetically sealed container is an unopened container that cannot be opened without breaking or damaging the container, seal, adhesive tape, or any other attachment which may protect the contents against the entry of micro-organisms.

Apple juice fermenting in carboys. (Image Source: beerik.com)

Pasteurisation of apple cider vinegar

The packaged product is pasteurised at 65 to 85 °C for 3 minutes. Pasteurisation may also be performed prior to packaging.

Cooling of pasteurised apple cider vinegar

The pasteurised product is cooled with water to 4 to 5 °C by passing the containers through a cold water misting tunnel or by immersion in cold water. Care must be taken to decrease the risk of thermal shock when using water that is too cold. After an initial cooling process, the containers are allowed to dry naturally or can be blow-dried.

Labelling of packaging

The packaging material or containers that are not pre-printed are labelled and coded with the necessary information. Various labelling and coding systems are available, depending on the type of label and container used.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric. za for more information.