Barbecue sauce

During barbecue-style cooking, barbeque sauce is used as a flavouring sauce, marinade, or basting for pork, beef and chicken. Barbeque sauce is a ubiquitous condiment that can be used on many other foods as well.

The ingredients of barbeque sauce vary depending on the recipe, and may even vary within different countries. The usual accepted ingredients, however, are vinegar, tomato paste (or mayonnaise or both) for the base of the sauce, and then liquid smoke and spices such as mustard and black pepper, and sweeteners such as sugar or molasses.

Process description

Barbeque sauce. (Image Source: Public Domain)

Ingredients

- 350 ml brown sugar

- 350 ml ketchup

- 120 ml red wine vinegar

- 120 ml water

- 15 ml Worcestershire sauce

- 35 ml dry mustard

- 10 ml paprika

- 10 ml salt

- 7,5 ml black pepper

Method

Combine the brown sugar, ketchup, vinegar, water and Worcestershire sauce in a blender. When properly combined, season with mustard, paprika, salt, and pepper and continue blending until smooth.

Cheese sauce

Choosing the appropriate cheese: Not all cheeses melt in the same way when heated. Some will in fact not melt at all, but instead become stiffer and drier when heated. On the other hand, some good melting cheeses are not suitable for sauce making, as they do not fare well in liquids. Avoid cheeses that are manufactured using acid instead of rennet. These cheeses include most fresh goat milk cheeses, ricotta, queso blanco and Indian paneer.

Cheeses manufactured with rennet have a soft, malleable structure that melts when heated, whereas cheeses manufactured using acid, allow the water in the cheese to be repelled when the cheese is heated. This in turn causes the proteins to stick together and form hard lumps.

Cheese sauce. (Image Source: Public Domain)

The age of the cheese also plays a major part in how the cheese will react to a sauce. As cheese is aged, the ageing process adds flavour enhancement but also causes the fats and proteins to break down into shorter strings. When an aged cheese is then melted, it has less ability to blend, which results in a sauce that is grainy. One way of bypassing this grainy texture while still adding the flavour that an aged cheese will impart to the sauce is by blending aged and younger cheeses.

This will ensure a cheese sauce with a good flavour profile and a rich, velvety consistency.

Factors that influence the quality of a cheese sauce

- When making a cheese sauce, it is important to always add the cheese last and then only heat the sauce long enough for the cheese to melt. The less the cheese is heated, the better. Never let the sauce boil as this will cause the cheese to become tough and curdle. It is advisable to use the residual heat from the pan to melt the cheese.

- While the whole cheese is cold, break it down as small as possible by shredding, crumbling or dicing the cheese. Small pieces will be quicker and easier to incorporate into the sauce, and working with the cheese while it is cold makes for easier handling.

- After the cheese has been reduced to smaller pieces, allow it to sit at room temperature, as this will allow the cheese to melt faster when added to the hot liquid.

- Keep stirring to a minimum to prevent the cheese proteins from forming globs.

- Use a thickener (cornstarch or potato flour) to prevent the cheese from curdling.

- Adding lemon juice or wine (in other words an acidic ingredient) will prevent the cheese from becoming stringy. Sprinkle the acidic agent over the shredded cheese before heating.

- Reduced-fat cheeses take longer to melt and are tougher. Shred reduced-fat cheese very finely and melt it over very low heat.

- Do not substitute milk or half-and-half when a formulation calls for cream, as the higher fat content in the cream will help prevent curdling.

- Do not add too much cheese. Although the flavour of the cheese will improve the taste of the sauce, there also needs to be enough moisture to hold the cheese in suspension.

Process description

Steps for making a roux and béchamel sauce:

- Measure equal amounts of butter and flour.

- Dice butter into small cubes and melt in a saucepan over low heat.

- Once the butter has melted, begin whisking in the flour.

- When all the flour is incorporated, continue stirring and cooking the sauce for a few minutes to activate the starch granules.

- If making a white or light-coloured cheese sauce, keep the heat low enough so the roux does not brown.

- Add milk. If the roux is hot, the milk should be cool, but if the roux is cool, the milk should be hot. Combining the two ingredients at different temperatures ensures they will heat up at a moderate rate, in other words not too fast or too slow, creating a smooth sauce.

- Whisk the mixture until smooth; add seasonings as required.

- Allow the sauce to simmer until it has lost its “floury” taste (approximately 20 minutes). Strain out any seasoning or lumps.

- Remove the pan from the heat and gently blend in the cheese. If the cheese appears not to melt, return the pan to very low heat. Watch it carefully and remove as soon as the cheese is melted.

- Avoid high heat. Temperature abuse can coagulate the proteins in the cheese and cause a separation of fats and solids.

Cottage cheese

Cottage cheese. (Image Source: healthline.com)

Cottage cheese is categorised as a cultured dairy product. Cottage cheese is the product obtained from a coagulated milk, cream, partly or wholly skimmed milk, reconstituted (prepared) milk, or a combination of these products. Cottage cheese is a soft, unripened cheese containing about 80% moisture. Cottage cheese can also be made with various additions such as herbs, pickles and spices.

Cottage cheese is classified as follows:

- Full fat cottage cheese may also be named cottage cheese, full cream cottage cheese, and creamed cottage cheese with the fat in dry matter content of at least 45%, but not more than 60%.

- Medium fat cottage cheese with the fat in dry matter content of at least 25%, but not more than 45%.

- Low fat cottage cheese with the fat in dry matter content of at least 10%, but not more than 25%.

- Fat-free cottage cheese may also be named skim milk cottage cheese, with the fat in dry matter content of at least 10%. Yield: 1 kg full fat cottage cheese from approximately 4,74 kg of whole raw milk and 1 kg low fat cottage cheese from approximately 7,48 kg of whole raw milk.

Process description

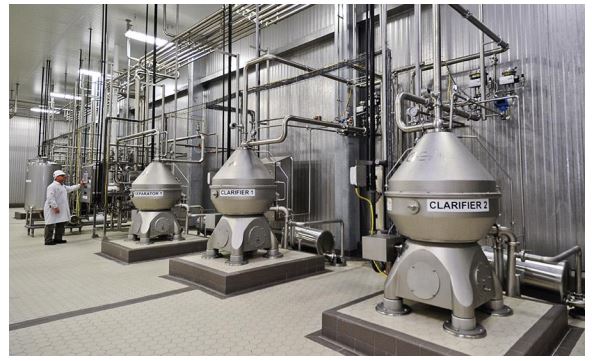

Clarification of milk. (Image Source: dairyfoods.com)

1. Storage of raw milk for processing

Milk is a highly perishable product that may turn sour if left at room temperature. Milk is cooled to improve its quality and stability. Milk leaves the cow at ± 37 °C and must be cooled within three hours to 4 °C. During cold storage, the milk must be stirred gently to prevent a cream layer from forming on top (cream separation by gravity). Raw milk is thus kept in large vertical tanks at the factory or processing plant (2 500 to 150 000 litres) fitted with one or more propeller agitator(s) until further processing proceeds.

2. Clarification of milk

Clarification is the removal of solid impurities (dirt particles, white blood cells and cells of udder tissue) from milk, prior to further processing. Clarification is achieved through filtration. Milk may be filtered through a perforated strainer, fine-wire mesh, or woven cloth (melkdoek) in small dairies. Medium and large dairies use replaceable in-line filters situated before the heat exchanger.

3. Pre-heating of milk for separation

Prior to separation, the milk is heated to 45 to 60 °C to ensure effective separation of the skim milk and cream phase. Heating also inactivates the enzyme lipase that is responsible for the development of rancidity in fats. Pre-heating guarantees the highest possible cream quality, that is the lowest amount of free fat in skim milk. Heating takes place in a batch vessel or in a plate heat exchanger.

4. Separation and standardisation of milk for cottage cheese

Standardisation involves the adjustment of the fat content of milk to obtain a product with a defined, guaranteed fat content. Cottage cheese products are classified according to their fat content. The fat content of milk must therefore be adjusted and standardised accordingly since the fat content of raw milk varies. Standardisation is preceded by separation of the milk and cream, and then re-mixing the two fractions in the desired proportions.

Take note: Fat-free cottage cheese is made from skim milk and does not require remixing but only separation. Separation: The cream fraction of raw milk is separated from the skim milk by passing pre-heated raw milk (45 to 60 °C) through a conventional or hermetic centrifugal separator.

A centrifugal separator consists of a stack of conical disks kept apart by strips of metal to form separation channels. The milk is fed into a central inlet tube into the bowl and enters the channels at the outer edge at the bottom of the clarifier. The centrifugal force separates the fat and water phase of the milk. Any solids that may be present are collected at the bottom and discarded. Centrifugal separators thus aid the clarification process.

Conventional separators: Conventional separators operate at atmospheric pressure and air is therefore present in the product. Hermetic separators: Hermetic separators on the other hand are airtight and operate under pressure, thus reducing the air present in the product. The skimming efficiency is increased by 0,01 to 0,02%. Hermetic separators treat the milk gently and with minimum damage to the fat globules.

Standardisation: Standardisation follows directly after separation. Various standardisation methods are available. The method depends on the size of the processing plant and the amount of automation employed during the processing.

Batch standardisation: This method is mostly used by small processing plants. It entails the mixing of a calculated quantity of skim milk, cream or full fat milk with the incoming batch of raw milk to obtain a product with a specific fat content. The quantities of the various fractions needed for batch standardisation can be calculated using Pearson’s Square. To be able to do this, the fat content of the various fractions must be known.

Continuous or direct standardisation: Large processors can afford to invest in automatic, in-line equipment for continuous standardisation. The raw milk is first skimmed (separated) by passing through separators in an in-line system. The fat content of the skim milk and cream fractions are determined and automatic standardisation takes place by re-mixing the required amount of cream with the skim milk. The remaining cream or skim milk is diverted and the standardised milk is ready for further processing.

5. Homogenisation of milk for cottage cheese (optional)

Homogenisation is the process where the fat globules in the milk products are finely distributed to reduce “creaming”, that is the separation of the cream and skim milk. Homogenisation can be seen as a special type of emulsification process. It is an expensive process that is usually not performed on small scale by batch operators. Large-scale processors include homogenisation as part of the continuous pasteurisation process. Homogenisation is performed after pre-heating the milk (regenerative heating step of continuous pasteurisation) because homogenisation is most effective when the milk is slightly heated (60 to 70 °C).

Homogenisation is accomplished by forcing the milk through a small opening at high velocity to cause disruption of the large fat globules to form small, stable fractions. The pre-heated milk enters the homogeniser at 60 to 70 °C, and is homogenised at a pressure of 15 to 25 MPa (150 to 250 bar). A twostage treatment is recommended. Two homogenising heads are used in series. The homogenisation head consists of a high-pressure positive pump that forces the milk through a narrow gap in a specially designed valve. The high pressure on the inlet side causes the fat globules in the milk to break up. Homogenisation takes place at the first homogenising head. The second head operates at a lower pressure and is used to break up any remaining clumps of fat globules. Homogenisation is an optional process. It has advantages for cheese processors, but also disadvantages. The processor must decide which is more important.

Advantages of homogenisation for cottage cheese:

- The uniform distribution of the fat globules,

- producing a smooth and creamy cottage cheese,

- a whiter coloured product.

Disadvantages include the following:

- the milk cannot be separated (cream and skimmed milk),

- increased sensitivity to sunlight leads to the development of a metallic taste,

- increased sensitivity to lipase (enzyme), and

- low stability of the protein to temperature variations.

6. Pasteurisation of milk for cottage cheese

Pasteurisation is a milk heat treatment that destroys all vegetative pathogens and heat-sensitive enzymes so that the phosphatase test gives a negative result.

Pasteurisation thus improves the keeping quality. Although cottage cheese can be made from unpasteurised milk and is considered to have a better flavour and aroma, the milk is usually pasteurised to eliminate microbial competition for the starter culture.

Various pasteurisation methods are available, depending on the size of the processing plant. Batch pasteurisation: This method is suitable for small operations with less than 2 500 litres of milk per day. The milk is pumped into an open vat or jacketed vat fitted with an agitator where it is heated. The milk is held at least 30 minutes at 65 to 73 °C followed by cooling within 30 minutes to 30 °C.

Continuous pasteurisation: Large processing plants use a continuous high-temperatureshort-time (HTST) method. Milk is heated quickly to 72 to 75 °C for 15 to 40 seconds in a plate heat exchanger. Five stages of heat exchange can be identified:

Regenerative heating: The incoming milk is pumped to the regeneration section of the heat exchanger where it is heated to 0 to 65 °C by heat transfer from freshly pasteurised milk. Up to 92% of the required heat can be recovered in this way. Milk may leave the pasteuriser at this stage to be homogenised and return to the next section.

Heating: Milk is further heated indirectly with hot water, vacuum steam, or saturated steam at atmospheric pressures to the required temperature (75 to 85 °C).

Holding: The hot milk is held at the required temperature in a chamber or a holding pipe for 15 to 20 seconds. The dimensions of the holding pipe must be sufficient to ensure the required residence time and flow rate of the milk. The stainless steel holding pipe slopes upwards and excludes trapped air. The temperature at the end of the pipe is continuously monitored to ensure sufficient pasteurisation. If the required temperature is not maintained for long enough, the milk is returned to the heating and/or holding sections via the flow diversion valve.

Regenerative cooling: The hot milk from the holding section goes to the regeneration section where it is cooled to 10 to 20 °C by heat transfer to the incoming milk.

Cooling: Milk is further cooled to 30 °C, first with cold water and finally with chilled water or refrigerant (brine or polyalcohol solutions). The higher the fat content of the milk, the higher the final temperature of the cooled milk will be. This prevents the milk from thickening, resulting in clogging of pipelines and filling problems. The mechanical action involved in pumping and filling thick, cold milk could also cause damage to the fat globules.

Take note: It is required by law in South Africa that processors keep thermo-graphic recordings of the temperature of pasteurisation for at least four weeks; and that apparatus used must be calibrated monthly to ensure the correctness of the pasteurisation process.

7. Inoculation and incubation of milk for cottage cheese

Inoculation is the addition of starter cultures to a food substance to initiate fermentation reactions. The warm milk (20 to 22 °C) is pumped into the fermentation tank and inoculated with a 0,75% starter culture mixture containing Streptococcus lactis. The milk and starter culture are mixed thoroughly to ensure even dispersion of the culture in the milk. The inoculated milk is incubated at 21 °C for 14 to 16 hours to allow fermentation to take place until the pH is reduced to 4,5. Fermentation is defined as the conversion of the milk sugar (lactose) into simpler substances such as acids by the action of the starter culture and enzymes. The fermentation tanks are insulated to ensure that an even temperature is maintained throughout the incubation period. They are also fitted with rotating stirrers.

8. Rennetting of milk for cottage cheese

Rennetting aids the coagulation of milk proteins to produce a coagulum or curd that traps the milk fat. This is achieved by the addition of rennet to the fermenting milk. Rennet is an enzyme preparation that was once isolated from the fourth stomach (abomasum) of a calf. Today rennet can be cultivated microbiologically. The rennet is a liquid to which salt, propylene glycol and a preservative (sodium benzoate) may be added. This preparation is stored at 4 °C and diluted with cold water prior to addition to the milk. Between 1 and 2 ml of rennet is added to 450 litres of milk to aid coagulation of the milk. The milk is stirred with the rotating stirrers of the incubation vat to prevent fat separation. The temperature of the milk is raised to 30 to 32 °C and the rennet added. It is then left to set (coagulate) and must remain undisturbed to ensure that a ‘gel’ is formed.

Cottage cheese (Image Source: Pixabay)

9. Cutting of coagulum for cottage cheese

The coagulum is then cut with vertical and horizontal knives into small cubes of between 0,5 and 1,2 cm. This eases the whey separation or syneresis by increasing the exposed surface areas. The cubes of curds and whey are gently stirred to prevent lump formation. Some whey may be removed at this stage. The curd is then left to rest for about 15 minutes.

10. Scalding of cottage cheese curds

Scalding is a heat treatment given to cheese curds to regulate the texture and acidification of the curd. The curds are slowly heated to 55 °C to accelerate the whey separation. Slow heating is necessary to prevent case hardening. The curd-whey mixture is stirred as soon as the required temperature is reached to ease separation.

11. Draining of whey from cottage cheese

Draining aims at removing excess free moisture from a product by gravitation force to obtain partial drying of the product surface. The whey and the curd have separated due to cutting, stirring and scalding. The whey is drained off either through a tap or by gravity separation.

12. Washing of cottage cheese curds (optional)

The curds can be washed 2 to 3 times with potable water at 30 to 32 °C, 14 °C and 4 °C, respectively. This cools the curds, removes excess acid and lactose and thus inhibits further acid formation through fermentation.

Cottage cheese packaged. (Image Source: healthline.com)

13. Draining of washed cottage cheese curds

The water is removed from the curds by draining it off either through a tap or by gravity separation.

14. Seasoning of cottage cheese (optional)

Salt and other optional seasonings such as peppercorns and herbs may be added at this stage.

15. Filling and sealing of cottage cheese

The containers are filled by automatic injection nozzles in large processing plants. Small processors can hand fill and seal the containers. Suitable containers include plastic tubs with foil and/or plastic lids. The containers should be hermetically sealed and stored at 4 °C. A hermetically sealed container is an unopened container that cannot be opened without breaking or damaging the container, seal, adhesive tape or any other attachment which may protect the contents against the entry of micro-organisms.

16. Labelling

Cottage cheese containers are labelled or pre-printed with the necessary information. The label information and presentation must be in accordance with the requirements set out in the Labelling and Advertising Regulations (R2034/1993). Also take note of regulations relating to Dairy Products and Imitation Dairy Products R 2581 of 20 November 1987 (as amended by R 1059 of 3 June 1988; R 2141 of 6 October 1989 and R 1465 of 26 August 1994).

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.