Soya sauce is the dark brown liquid extracted from a fermented soya-wheat mixture. It has a salty taste and sharp flavour. It is used as an all-purpose seasoning. Soya sauce is prepared from soya beans mixed with other cereals such as wheat that undergo two separate fermentation processes.

All the enzymatic and biological reactions taking place during these two fermentation processes, together with concurrent chemical reactions, lead to the formation of many volatile and non-volatile substances. These substances are responsible for the characteristic colour, flavour and taste of soya sauce. A wide variety of traditional soya sauce recipes were passed on from one generation to the next.

All the different cultures of the East seem to have their signature soya sauce products. This report will describe a basic process for the manufacture of Chinese and Japanese soya sauce.

Soya sauce. (Image Source: motherearthnews.com)

Process description – Chinese soya sauce preparation

The initial steps in the preparation of Chinese soya sauce are essentially the same as for making Chinese soya paste (Jiang). The final stage of preparation involves the extraction of the sauce from the fermented mass.

Treatment of soya and cereals prior to inoculation

Whole soya beans or defatted soy flour can be used. After cleaning, the soya beans or flour is soaked for 3 to 5 hours in water and drained before being steamed for 40 minutes. Cooking is a very important step that enhances starch and protein digestibility for the Koji starter culture and thus ensures the desired final texture of the paste. The cooked soya beans are then cooled to 80 °C before it is mixed with wheat. Wheat bran or flour is steamed or roasted before being mixed with the hot soya beans. The ratio of soya to wheat is generally 60:40. The mixture is allowed to cool to 38 to 40°C before being inoculated with the starter culture.

Different brands of soya sauce. (Image Source: seriouseats.com)

First fermentation

The treated soya and wheat mixture is inoculated with a special strain of Aspergillus that causes fermentation of the product and the formation of “Koji”. The concentration of starter used is between 0,1 and 0,2 %. The direct translation of “Koji” is “bloom of moulds”. The Koji provides the spores of microorganisms needed to make soya sauce. Fermentation takes place in open pans under controlled temperature (36 °C), airflow and relative humidity (>90%).

The mixture is occasionally stirred to release internal heat generated by fermentation and to ensure sufficient aeration of the mixture. The first fermentation stage is usually complete after 24 hours when the mixture turns olive green. The resulting product is known as mature Koji and is regarded as an intermediate product of soya paste and sauce manufacturing.

Koji moulds contain a great variety of enzymes that digest the starch, protein, and lipid components of the raw material. During the first fermentation process, the major components of the raw materials are broken down to smaller components including peptides, amino acids, maltose, glucose, free fatty acids and glycerol. These smaller components are fermentable substrates that support the growth of yeast and lactic bacteria that are active in the second (brine) fermentation.

Second fermentation

The matured Koji is now mixed with a small quantity of warm brine and packed in fermentation vats or tanks. The anaerobic conditions favour yeast and lactic bacteria that originate from Koji starter culture. These organisms are responsible for the breakdown of the fermentable substrates (mainly sugars) to acid, alcohol, and other volatile and non-volatile substances that contribute to the quality of the final product.

Temperature is a particularly important factor during fermentation, and determines not only the duration of the fermentation process but also the quality of the end product.

The mixture contains about half the volume of brine and 25% less salt compared to the mixture used for soya paste. These changes, along with high fermentation temperatures (40 to 45 °C), reduce the fermentation period to 3 weeks.

Heat stabilisation of fermented mash

The fermented mash is transferred to another tank, mixed with additional brine, and heated to over 80 °C.

Extraction of soya sauce

The heated mass is allowed to stand and settle before the supernatant is removed. This liquid is known as raw soya sauce.

Preservation of soya sauce

The raw soya sauce is mixed with benzoic acid to preserve it.

Clarification of soya sauce

The sauce is clarified by passing it through filters.

Japanese soya sauce. (Image Source: thetruejapan.com)

Process description – Japanese soya sauce preparation

The basic steps for the preparation of Japanese soya sauce are similar to Chinese soya sauce, but the end products can differ significantly.

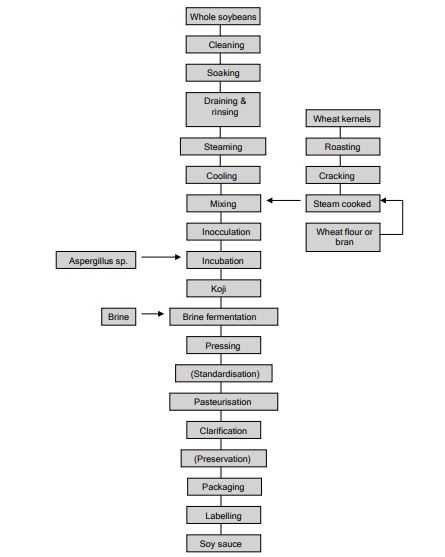

The process can be summarised as follows:

- Treatment of raw materials

- Koji preparation

- Brine fermentation

- Pressing and

- Refining

Treatment of raw materials

The soya beans and wheat are prepared separately but simultaneously. Whole soya beans are soaked in water for 8 to 12 hours (overnight) at 30 °C to increase the moisture content of the beans. The soak water should be changed every 2 to 3 hours to prevent the possible growth of undesirable Bacillus.

The soaked soya beans are then cooked in open pans or steam-pressure pots until soft.

If defatted soya flakes are used, it should be cleaned and moistened with misters. The quantity of water used should be 30 % of the weight of the soya flakes. The moistened flakes are then pressure-cooked for 45 minutes. The cooked soya beans or flakes are rapidly cooled to below 40 °C. This is accomplished by constant stirring or spreading out on perforated belt/tray coolers.

The treatment of the wheat is concurrent with that of the soya beans. Whole kernel wheat is roasted and cracked in rollers. Wheat flour and bran can also be used. The cracked wheat or flour is moistened and steamed.

Koji making

The pre-treated soya beans and wheat flour is mixed in the desired proportion, according to the recipe used and the type of end product desired. The ratio can vary from 1:1 (soya beans: wheat) to as high as 9:1. The mixture is inoculated with Koji from a previous batch (seed Koji), or with pure cultures containing Aspergillus oryzea and/or A. sojae. Pure cultures are added at a concentration level of 0,1 to 0,2 %.

The inoculated mixture is placed in shallow, perforated vats and kept in incubating rooms with controlled conditions. Temperatures are controlled at 30 to 35 °C initially and reduced to 20 to 25 °C towards the end of the incubation period. Occasional stirring is necessary to aerate the mixture and release the heat generated inside the mix. The mixture turns green-yellow after 3 to 4 days and is now known as mature Koji.

Brine fermentation

Mature Koji is mixed with an equal volume of brine to form a liquid mash. The salt concentration of the mash should be 17 to 19%. The mash is kept in large fermentation tanks for several months for completion of the brine fermentation. The temperature of the mash inside the tanks can be me mechanically controlled. Although higher temperatures shorten the fermentation period, a better quality product is produced under lower temperatures.

A good quality soya sauce can be manufactured in six months by controlling the temperature at 15 °C for the first month, followed by 28 °C for four months and finally returned to 15 °C for the last month. Occasional stirring is necessary to provide enough aeration to promote good yeast activity and prevent the growth of undesirable anaerobic micro-organisms, and to facilitate the removal of carbon dioxide. The fermented mash should have a reddish-brown colour and pleasant aroma.

Pressing of the fermented mash

The mature mash is filtered through a cloth and pressed in a mechanical or hydraulic press. The filtrate that is obtained is known as the raw soya sauce, and is stored in a tank to allow for precipitation of suspended matter and floating of oil on the top.

Adjustment of salt concentration

The salt and nitrogen concentration of the soya sauce can be adjusted at this point to meet standards of identity.

Pasteurisation of soya sauce

The sauce is pasteurised at 70 to 80 °C.

This heat treatment prior to clarification is very important, and serves the following purposes:

- Inactivation of enzymes and micro-organisms, thus stabilising the product

- Enhancement of the unique product aroma

- Darkening of colour

- Induction of flock formation, which facilitates clarification

Clarification of soya sauce

Soya sauce is clarified by sedimentation or filtration. Filter aids such as kaolin, diatomite, or alum may be added to enhance clarification before filtration.

Addition of chemical preservatives (optional)

Some processors prefer to add preservatives such as sodium benzoate and paraoxybenzoate.

Packaging and labelling of soya sauce

The soya sauce is filled in bottles or cans, and labelled with the necessary information.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.