The quality of the earth under a dam is of utmost importance. Careful surveying of the nature and depth of the topsoil and subsoil must be done by drilling or sinking test holes (especially at higher walls) over the foundation floor, the basin and the area downstream of the wall.

The results of the survey, that is the type of soil and geological condition, will determine whether an earth dam can be built on a specific site and will influence the design thereof.

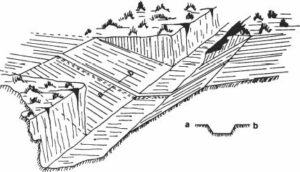

Figure 1: Excavations for a dam wall.

Requirements for a good foundation

- The soil below the wall must be of a dense nature to be compacted economically. The dense material must be at least one metre deep and must preferably be the same as the building soil of the wall.

- It must be able to bear the weight of the structure safely.

- Avoid plastic clay, expanding clay or marshy types of foundations. Also, avoid foundations of turf and highly dispersive soil.

- Avoid porous foundations, for example sand, gravel, and deep layers of pebble stone, to prevent large-scale seepage.

- Saturating (seepage) of the foundation material reduces stability and increases the tendency for the topsoil to slide.

The base of the wall being prepared.

Preparation of the base of the wall

- Plough the floor width at least 0,15 m to 0,25 m deep.

- Remove the humus-rich and false top layer, vegetation and ant heaps from the entire foundation surface.

- The key trench is excavated to at least 0,6 m deep in a dense layer with minimum side slopes of 1:1 for the entire length of the wall.

- Plough the base area once again, moisten and consolidate.

- If the foundation is marshy, remove that portion as a whole down to good foundation material. If it is not removed, the soft material will be extruded by the weight of the wall. The wall will sag; cracks will develop through which water may flow and wash the wall away.

- A shallow, porous top layer, for example sand, gravel or other permeable material, must be removed over the entire base area of the wall up to the dense soil, clay layer or rock.

- Over dongas, the side walls must be sloped down to a slope of 1:1. Remove all loose material from the floor of the gulley and provide the wall with a key trench. Ensure a good bond between all the materials and build the earth wall up horizontally (Figure 1).

- The same procedure is followed with the repair of a break in the earth wall and where terrace forming banks occur on the floor of the dam wall.

- Deep porous top layers of sand and/or gravel must be consolidated in a wet condition and the dam is provided with a core or blanket up to the rock or clay.

- If a part or the entire foundation is a rock ridge, it must be cleaned thoroughly. All cracks and crevices must be filled with cement mortar and the dam wall must be provided with a concrete key wall.

Soil for building the dam.

The wall

The wall must be dense and stable.

Soil for building the dam

- Gravel: Mass and stability is good, but it is porous and lacks cohesion.

- Sand: Unstable, porous and without cohesion.

- Loam: Dense but permeable and unstable, and usually contains an undesirable high percentage of organic material.

- Silt and clay: Dense but permeable and unstable. It expands when damp and shrinks when dry. It therefore cracks easily. It is good for building the centre wall area and pit walls.

- Turf and highly dispersive/sodium affected soil is unsuitable for dam building.

- Good building soil must be heavy and well graded to ensure minimum hollows and maximum density after consolidation. The desirable clay content is from 20% to 40%. The clay content can be determined in the field as follows:

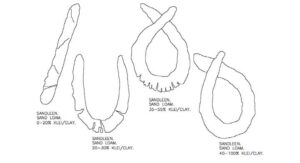

- Take a handful of moist soil, kneed it and roll it in the hands to form a “sausage”. The relation between the sausage and clay content is given in Figure 2.

- If ungraded soil and soil that shrinks and swells with increase or decrease of moisture content needs to be used, place it in the inner area in the rear, where it is subject to minimum moisture changes and is under a load.

- Sufficient amounts of suitable building soil should be close at hand and easily accessible. It should preferably be available in the dam basin.

Figure 2: Relation between the “sausage” and the clay content.

Cross section through the main dam wall

The cross section of an earth wall is in the shape of a trapezium. The following factors mainly determine the cross diameter of an earth wall:

- The height of the wall

- The soil or soils from which the wall is built

- Nature of the foundation

- Construction method

- The extent of the water surface area when the dam is full

- Position of the wall in relation to the prevailing winds

- Paving of the wall or not

The extent of the water surface area when the dam is full determines the cross diameter of a wall.

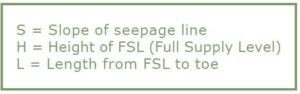

Possibility of seepage of water through the dam wall (Figure 3)

If a dam is built with permeable soil, it is possible that the saturation line of the water may reach the surface against the back slope of the wall, or in the soil directly beneath the downstream toe of the wall. If this occurs, there is a danger that the water that seeps through the wall can tunnel back from the rear and thus eventually lead to failure of the wall.

Slip (slip circles) and subsidence of the wall can also occur. The same dangers exist if seepage occurs through the foundation.

The nature of the building material in the wall and the nature of the foundation determine the degree of seepage through the wall.

The position and slope of the saturation line through the wall is determined by:

- Water permeability of the wall material and foundation material.

- Position and amount of groundwater flow at the site.

- The type and design of key walls and cut-off walls.

- The presence and position of drainage structures in the rear of the wall

If it is known where the saturation line cuts the rear end of the wall, provision is made in the design to eliminate seepage.

Figure 3: Flow lines through wall and foundation.

Seepage lines

All earth walls that store water develop a seepage line (Figure 3). The average hydraulic slope of the saturation line through the dam wall is S = H/L.

The average hydraulic slope of the saturation line

For dense, well-consolidated soil, S is steep, namely 4:1 average. For soils that are not dense or poorly consolidated soil, S is flat, namely 7:1 and flatter.

Requirement

The seepage line must cut the wall within its base. In order to comply with this essential requirement, the following must be done:

- The wall must be built with dense impermeable soil.

- Build the middle-third area with the densest soil and the outer thirds with permeable soil, or build the key wall with concrete that stretches from the dense foundation or rock to at least the FSL. The latter is the most efficient method to prevent seepage through the wall and underneath the structure. Polypropylene sheeting can also be used for this purpose.

- Enlarge the base of the wall by making the rear slopes flatter.

- Where seepage occurs through or underneath the wall, drain the toe and/or build an upstream blanket in the basin.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.