Rapid-exit parlours are designed to improve the efficiency of fishbone and parallel parlours. All the cows on the one side of the parlour are let out simultaneously in a direction perpendicular to the direction to which they entered the parlour. This saves the labourer time in letting out the cows. The time it takes for the cows to enter the parlour and the delay on account of slow milking cows remains unchanged.

Regulations concerning milking parlours

The following requirements are applicable to milking parlours:

An acceptable milking shed must consist of at least:

- A milk room where the actual milking is done;

- A milk handling room where milk is received from the milking parlour and stored or treated, processed, and packaged;

- A bathroom for the milking crew;

- A wash basin for the washing, cleaning, disinfecting and sterilisation of loose milk containers and other loose apparatus and equipment used in the handling of milk.

The facilities mentioned above must be erected as separate rooms in one building complex or as separate loose standing buildings. A scullery with a wash basin can be erected as an integral part of a milk room or as a separate room.

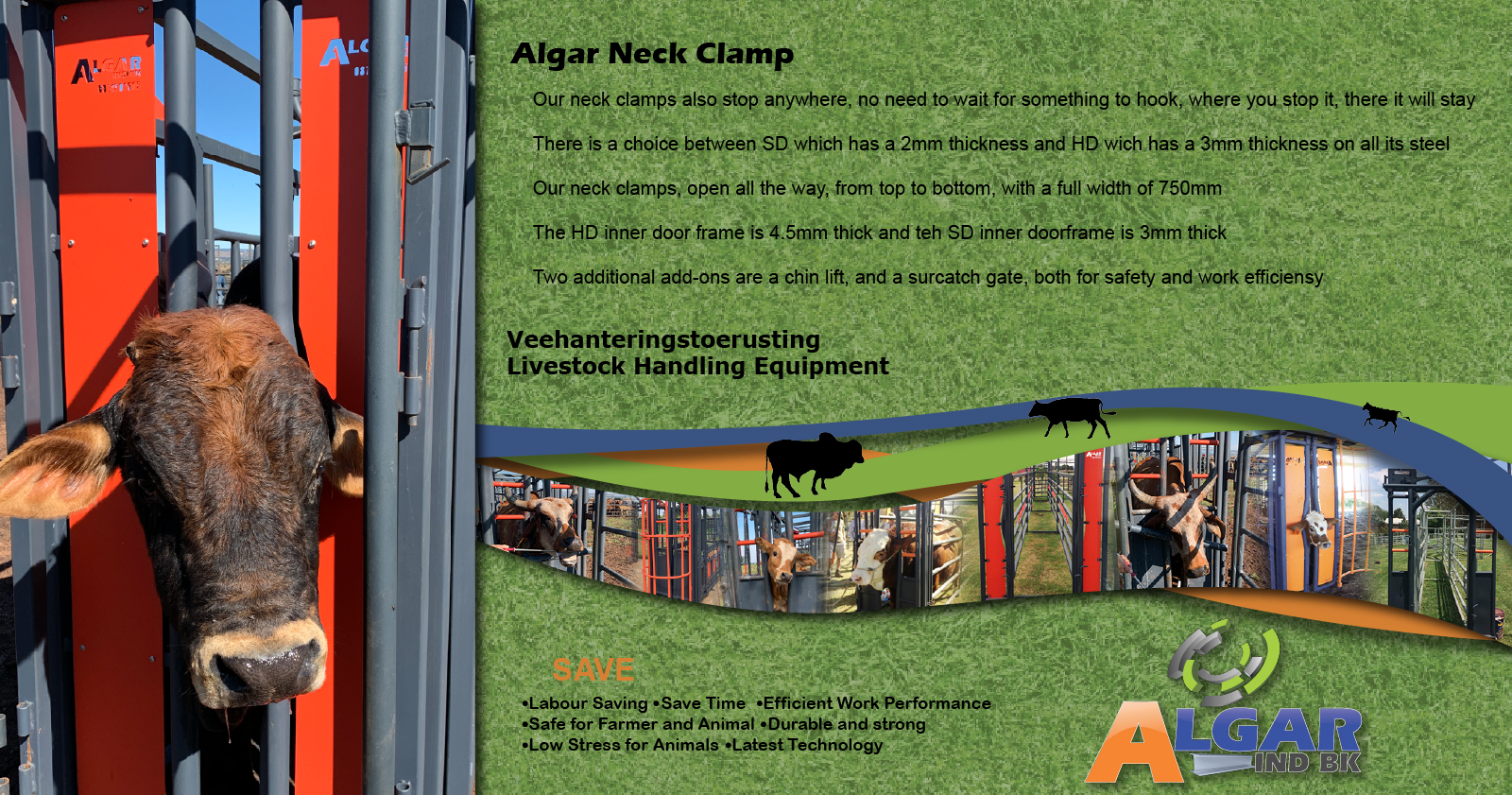

Rapid-exit parlour with hydraulic cylinders.

A milk room for milking:

(a) May not have any direct connection with a latrine or with a room in which there will exist or originate, from the nature of its activities, gases, smoke, vapours, dust or a soot deposit, except a fodder room or fodder storage room.

(b) Must provide standing room for more than one row of dairy animals parallel to each other, and must contain a separating alley of at least one metre wide between the rows.

(c) Its partitions, if any, to separate the diary animals from each other when they are milked, must be of smoothly finished non-absorbent and corrosion resistant material, without any open seams or cracks.

(d) Must be equipped in such a way that fodder that collects behind or under the troughs can be removed.

(e) Its exterior walls must:

•have an interior height of at least 2,4 metres;

•be at least 2,1 metres above the level on which the dairy animals are standing at the location where dairy animals are milked.

(f) The interior wall surface must be smooth and washable.

(g) Its roof must be of water resistant and washable material.

(h) Its floor must:

•be of leak proof and cleanable material;

• and drain thoroughly to a drain connected to a disposal system in such a way that no water pools can form on the floor.

(i) Must be sufficiently ventilated and illuminated.

(j) Must be provided with at least one water tap with pure running water, onto which a pliable pipe can be connected for washing purposes.

(k) Its entrances and exits for dairy animals must have a floor covering of an impenetrable surface, which is connected to a disposal system and such a floor covering must be so installed that any dairy animal that enters or leaves the milking parlour can walk at least a distance of four metres over it.

Picture 3: Rapid-exit parlour with hydraulic cylinders.

A milk handling room:

(a) Must comply with the stipulations

(a), (e1), (f), (g), (h) and (i) above.

(b) Must have sufficient room to (in addition to the storage of milk) clean and disinfect milk containers.

(c) Must be provided with at least one wash basin with pure running hot and cold water, lain on with pipes and with the drainage connected to a disposal system.

(d) Must be erected in such a way that a milk pipe of a milk tanker can be connected through a door to the mass farm tank and the distance between the two connections may not exceed 6 metres.

(e) Must be rodent resistant.

(f) Its doors and windows must be sealable against dust.

(g) Can be fitted with a mass farm tank for the storage of milk.

A bathroom must:

(a) Comply with the regulation under the section, A milk room for milking (e1), (f), (g), (h1) and (i).

(b) Have at least one wash basin and one shower fitted with pure running water lain on with pipes, for each fifteen or part of the number of persons working at the milk room and be provided with soap, a nailbrush and disposable towels and the waste water from such a basin and shower must drain to a disposal system.

(c) And be within easy reach of a milking parlour and milk room.

A milk room.

Effluent from a milk room may not:

- Be stored, treated or disposed of in any other place than in or on a disposal system;

- Be disposed of in another manner into or onto a disposal system or transported thereto than by means of a pipeline or cement trench or in a container;

- Be disposed of in such a manner that a water source is or can be polluted thereby. Only pure water may be used in a milking parlour.

- A supervisor must ensure that in or near a milking parlour:

- A nuisance or a life-threatening situation is not caused or arises;

- Poisonous or dangerous substances or gasses are not stored;

- No activity is performed that can pollute or be detrimental to the milk;

- Rodents and flies, cockroaches and other insects on the premises are combated.

A milking parlour may not be used for any other purpose than for the production and handling of milk. Loose milk containers and other loose apparatus and equipment used in the handling of milk may not be washed, cleaned, disinfected or sterilised at any other place than in the washing-up facility, which must be equipped with a proper wash basin. No-one may eat or use or handle tobacco in any form in the milking parlour. As soon as the dairy animals have left the milking parlour, all the manure must be removed from the parlour and the floor, and all entrances and exits of the parlour must be washed clean.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.