The interior design of your dairy can make or break your operation. With some clever thinking beforehand, your dairy will become a place of pride for generations to come.

Doors

Because dairy buildings usually have wet floors, it is advisable to saw off the doorframes 150 mm above the floor and build it up with cement. This will prevent rotting of wooden frames and rusting of steel frames. The doors, through which cows have to walk, must be at least 1,2 m wide (Smith, 1998).

Windows

The window surface in the milking parlour must cover a minimum of 15% of the total floor area and at least 50% of the window area must be able to open. Windows must be placed so that the entire parlour receives light during the day. Window sills must slope downwards to all sides and be finished off smoothly to prevent dust from collecting on them.

Roof

Use a flat or pitched roof of galvanised iron. A ceiling is not a prerequisite, but then the rafters have to be planed down smoothly and the rafters and underside of the roof must be painted with light coloured and washable paint. There must be no gaps between the roof and the walls.

Picture 1: Milking pit.

Milking pit

The pit length of a fishbone milking parlour is determined by the following formula (Engelbrecht, 1991).

Pit length (m) = 1,07 x number of milking points + 2,5

This represents the length taken up by a cow when she stands at an angle of between 30° to 45°, a distance of 1,5 m from the front of the pit, which is sufficient for mounting the end-unit and milk pump in its length along the side of the pit and an additional 1 metre on the back of the pit.

The depth of the pit is 850 mm to 865 mm and extends from the standing level of the cows to the floor of the pit. For foot space inside the pit, the pit wall is built slanting to the top with a deviation of 106 mm outwards on both sides. The vertical extension of the pit wall to the top (splash wall) extends 150 mm above the standing level of the cows and is 100 mm wide (Engelbrecht, 1991).

The width of the pit is normally 1,8 m and if bottles are used, it is 2,0 m. The width between milking units on both sides of the pit may not be smaller than 950 mm.

The pit floor is of concrete and 100 mm thick with a slope of 1:70 to the drainage canal in the centre of the floor or both sides of the pit next to the vertical walls. If the drainage canal is in the centre of the floor, it must be covered with a steel grate. As mentioned in the previous article, the pit floor and walls are tiled.

Picture 2: Manure canal with grate.

Platform

The manure canal in the platform on which the cows are standing must be covered with a galvanised iron grate to prevent cows from stepping into it (see Picture 2).

To obtain the standing position of a cow for a fishbone system between 30° and 45°, a gate is fitted at an angle of 30° to 45° on the front of the platform. If there are no feeding troughs in the milking parlour, a pipe/breast railing must be fitted at a height of 950 mm at the front and upper side of the platform to prevent cows from rubbing against the wall.

Rails placed around the pit on the platform, must be directly joined against the splash wall. The standing space widths for cows between the railings around the pit and the breast railing, which needs to be just a straight railing, vary between 900 mm for smaller breeds such as Jerseys to 1 000 mm for larger breeds such as Friesland (Engelbrecht, 1991).

Picture 3: A lot more space is needed around this milk tank.

Milk room

A free space of at least 800 mm must be provided around the tank. Also make provision for the storage of milk cans and other utensils with metal shelves, at least 500 mm above the floor surface (Smith, 1998). The walls must be at least 2,4 m to 2,7 m high with a smooth, light coloured and washable interior surface.

There may not be any sharp folds. Be careful when using conventional wall tiles, as the folds can offer breeding place for germs (Smith, 1998). A ceiling is not essential if the roof surface is smooth, light in colour and washable and dust cannot enter the room. A double door, garage door or roller door must be provided in a position closest to the loading point of the milk tanker. If the milk room and scullery are separate rooms, a sliding door must be fitted between the two rooms, while direct access between the milk room and milk parlour must have a solid door.

The window area must extend over at least 15% of the total floor surface and at least 50% of the window area must be able to open. Windowsills must be aslant to prevent dust collecting. Sufficient cross ventilation and artificial lighting must also be provided. For efficient drainage, the floor must be sloping at a gradient of 1:70 and floors must be at least 100 mm thick.

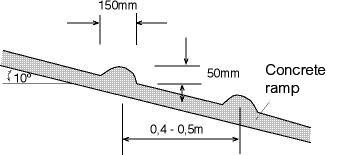

Figure 1: Construction detail of a ramp.

Scullery

The scullery is used for washing up of all dairy equipment. All the requirements concerning the construction of the milk room, except for the doors and size of the room, apply to the scullery.

Bathroom

The same regulations regarding construction, as applicable to the milk room and scullery, also apply here. Entry may only be allowed from a screened-off outer door. The minimum floor surface is 7 m2 with a minimum width of 1,8 m.

Machine room

The room must be large enough to accommodate the vacuum pump(s) and compressor(s) and to leave sufficient moving space around the equipment. The compressor of the milk tank is placed in the machine room opposite an opening in the back-to-back wall of the machine and milk room. Cool air is extracted from the milk room through the opening and creates a coolingdown effect.

Provision must be made for the application of a tractor or other power source, in the case of a power failure.

Office

For a better view, the office floor must be built 200 mm higher than the floors of the other rooms. A built-in cupboard is handy for storing medicines and machine parts (Smith, 1998).

Stairs

Cows feel safer on stairs than on ramps because their hooves always step on a horizontal level. The correct measurements for upward stairs are 600 x 150 mm, while downward stairs must be 500 x 80 mm. The surface of stairs must be non-slip. (Engelbrecht,1991).

Ramps

If ramps are used instead of stairs, the slope must not exceed 10%, with the minimum length 4,6 m and 0,6 wider than the entrance door. The surfaces of the ramps must also be non-slip.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.