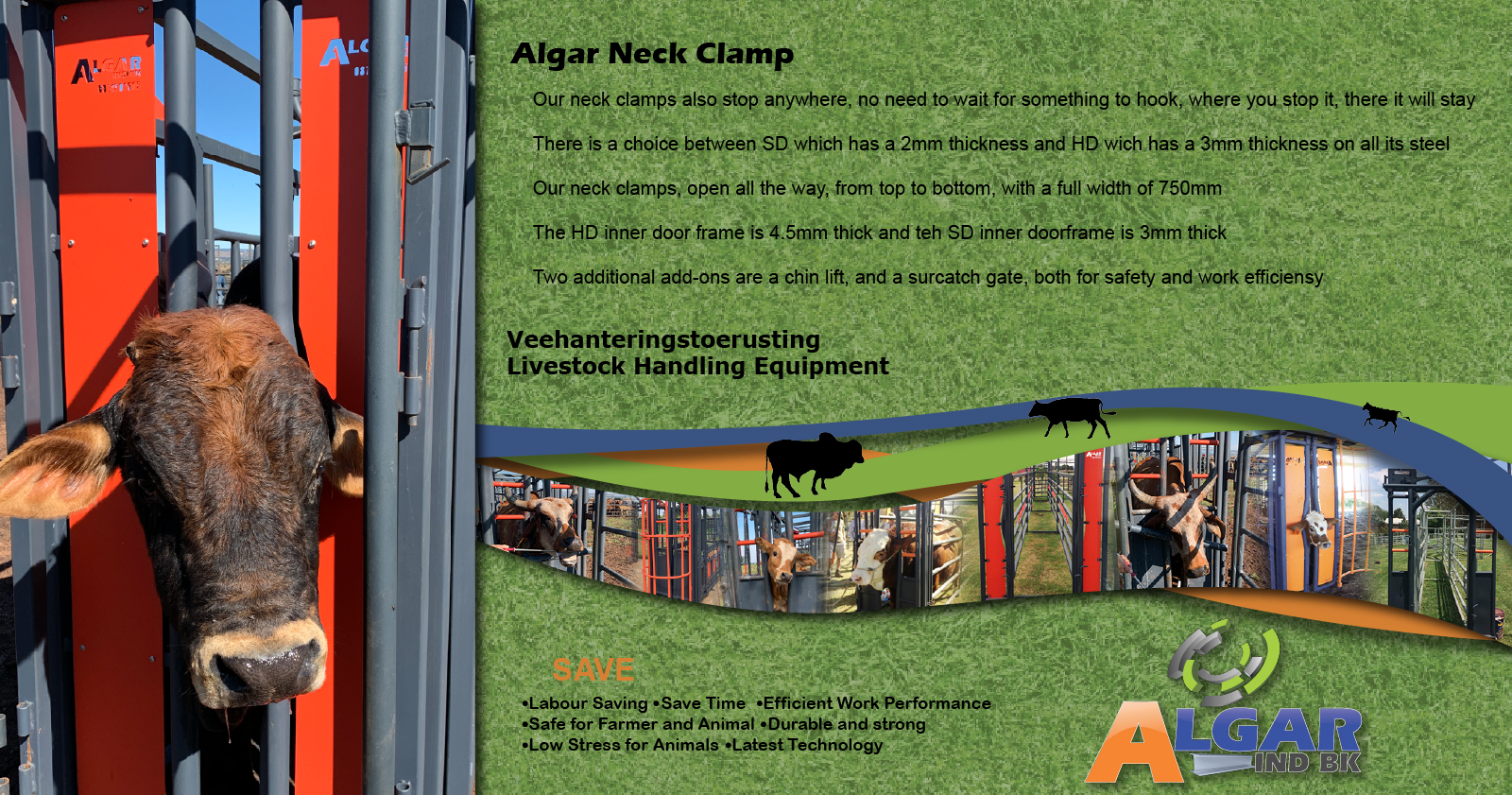

Fishbone milking parlour

Cows enter these parlours in groups and stand at an angle to the milking pit, so that only the udder part of the cow is exposed to the labourer (Figure 1).

Figure 1: Fishbone parlour.

This layout reduces the distance between the udders significantly and saves walking time and effort between milking points. The measurements of the majority of fishbone milking parlours are 965 mm to 1 114 mm.

Many variations of the fishbone parlour, sometimes called the ‘para-bone’, have been installed, which reduced the distance between cows to 760 mm and 860 mm. Standard fishbone parlours vary in size from 4 to 20 milking points at each side of the pit (Armstrong, 1993).

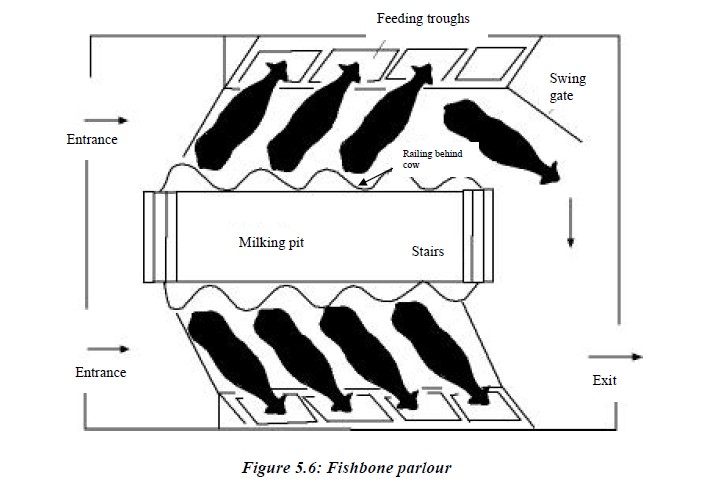

Figure 2: Polygon milking parlour.

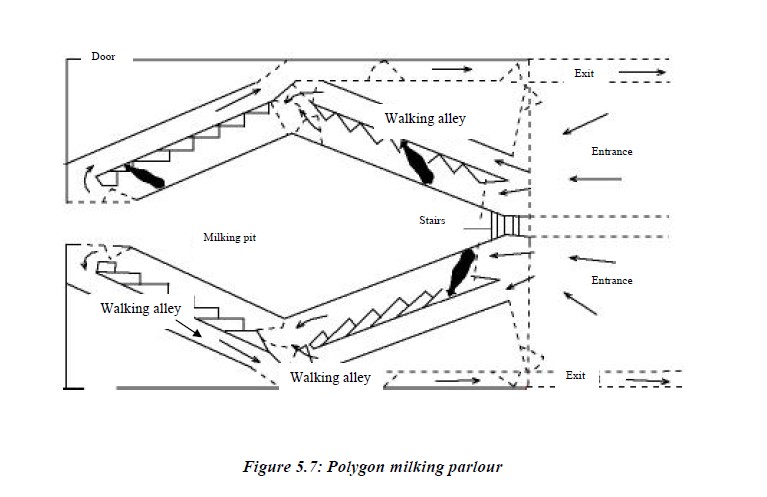

As the dairies grew larger, there was also a demand for larger milking parlours. Increasing the number of milking points in a fishbone parlour with a double row of milking points, made very little difference to the capacity. With larger milking parlours, the number of cows to be milked at one time increases and time is wasted during entry and exit. A cow that milks slowly holds up the other cows. This inspired the development of the polygon, a square fishbone parlour (see Figure 2) and the trigonal parlour, a three-sided fishbone parlour (see Figure 3).

Figure 3: Trigonal milking parlour.

With the development of speed-exit parlours (rapid exit) in the late eighties, fewer trigonal and polygon parlours were built (Armstrong, 1993). Fishbone parlours are suitable for dairies with 200 to 500 cows.

Benefits of fishbone milking parlours:

- Low construction cost compared to other milking parlours, because of the smaller floor surface.

- Minimum maintenance.

- Low cost per milking pit.

- Ideal for a herd still to be extended. A double row fishbone parlour can be built with only one side to be used initially, until the herd size warrants the use of both sides.

- Low labourer fatigue as udders are only 914 mm to 1 200 mm apart and claw pieces can be fitted quicker.

- The parlour is easy to clean because of the minimum framework and floor area.

It is alleged that cows adapt easier to a fishbone parlour as nervous cows are more confident because of the body contact with other cows.

Disadvantages:

- A cow that milks slowly delays an entire group.

Rotating parlour

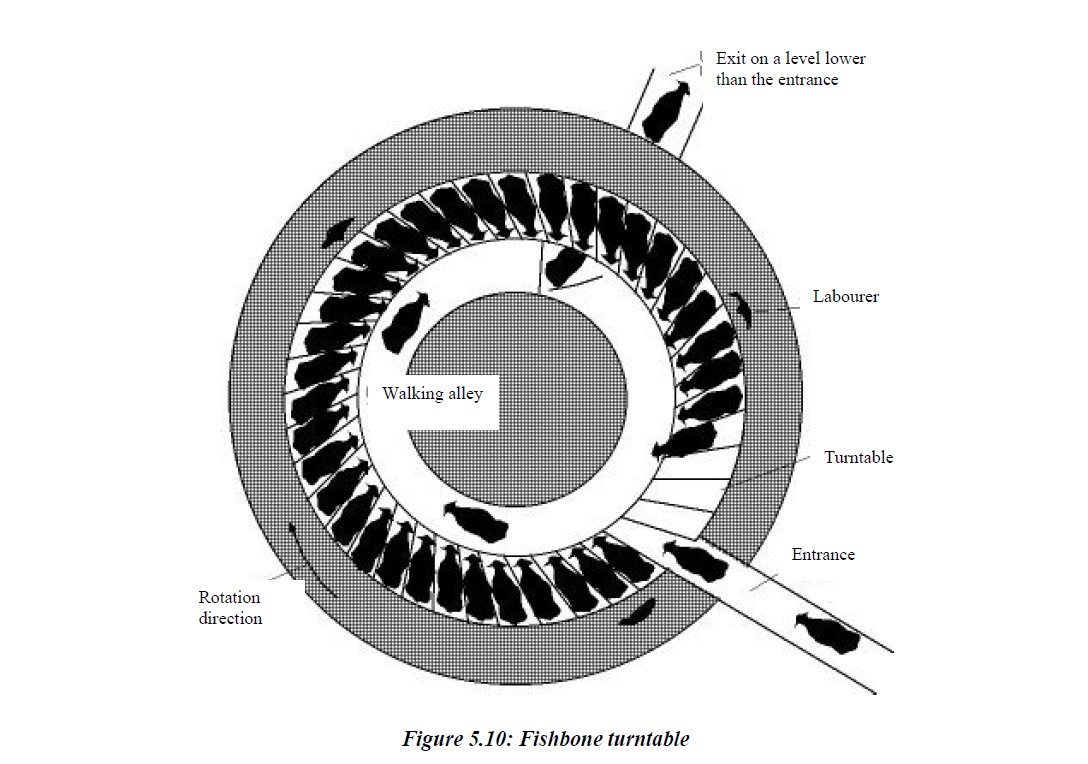

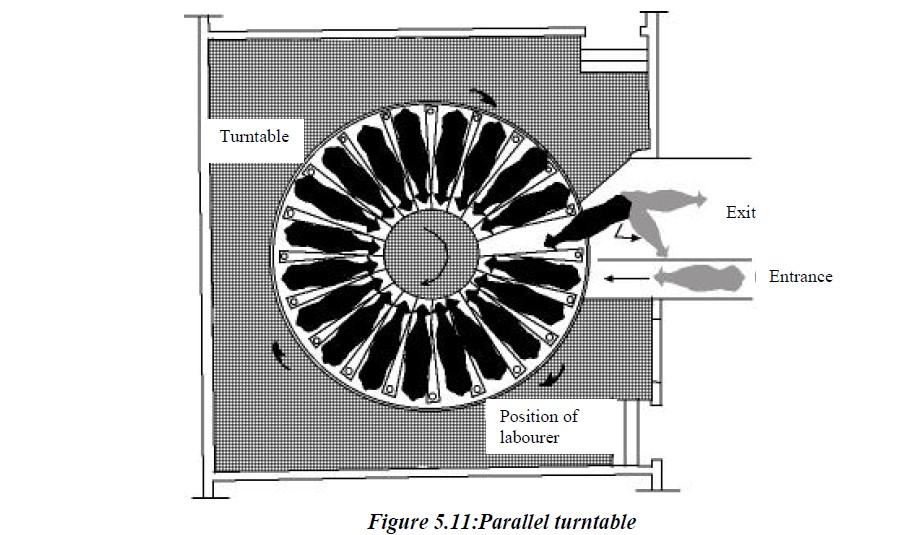

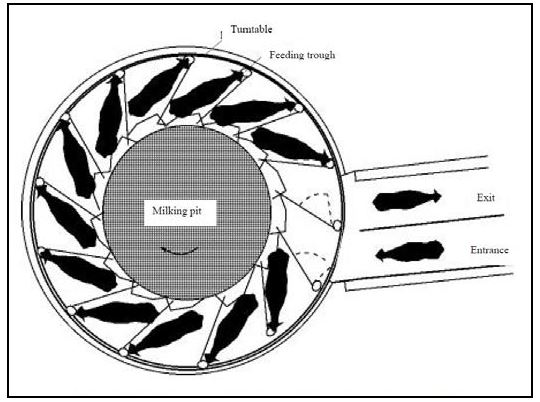

In this type of parlour, cows are milked on a rotational, raised, circle shaped platform. There are many variations of this type of parlour, based on the way the cows stand on the platform.

They can stand in tandem (see Figure 4), fishbone (see Figure 5) or parallel (see Figure 6) formation, with their heads directed towards the inside or the outside of the platform.

Figure 5: Fishbone turntable.

The most logical choice is the parallel type with the heads of the cows directed inward, as this takes up the least space per cow. The labourers remain in the same position on the outside of the platform, while the cows move in rotation towards them. The speed of the platform can be controlled to give the labourers sufficient time to prepare the cow and fit the claw piece (Engelbrecht, 1991).

Rotating milking parlours usually consist of round steel platforms that turn on rollers and are driven by electric or hydraulic motors. Another type of rotating parlour – which originated in New Zealand – consists entirely of concrete and has a platform that floats on a water pillow. This type of parlour’s drive requirement is a third of that of a conventional rotating milking parlour (Engelbrecht, 1991).

Figure 6: Parallel turntable.

One of the difficulties of rotating parlours is the possibility of injuries to cows when they enter or leave the parlour. New parlours, however, have various mechanisms to make provision for this risk, including light censors and crushes. The entrance gate allows only one cow to enter the platform at a time. As the cow moves through the gate, her progress is monitored by light censors, which makes the platform rotate slower or stop if she takes too long to climb on. If the springloaded

crush gate notices that the cow is being crushed, the rotation direction is reversed immediately to relieve the pressure. This prevents injuries to cows if they are crushed between the wall and the moving framework of the platform. With new generation rotating platforms, the cow controls the platform and not the labourer (Field, 1998).

Figure 7: Fishbone turntable with cows’ heads directed to the outside.

Benefits:

- High cow flow.

- Minimum walking distance for labourers.

Disadvantages:

- High cost compared to other types of milking parlours.

- Greater maintenance cost.

- Risk of mechanical failure that can end the entire milking process.

- The dairy cannot be extended.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.