Fresh-pack or quick process pickles (that is whole cucumber dills, crosscut cucumber slices, bread-and-butter pickles) are made by the addition of an acid such as vinegar and not by the natural fermentation of the vegetable.

The tart flavour of these easily prepared products is due to the acetic acid in vinegar. The product is further preserved by pasteurisation.

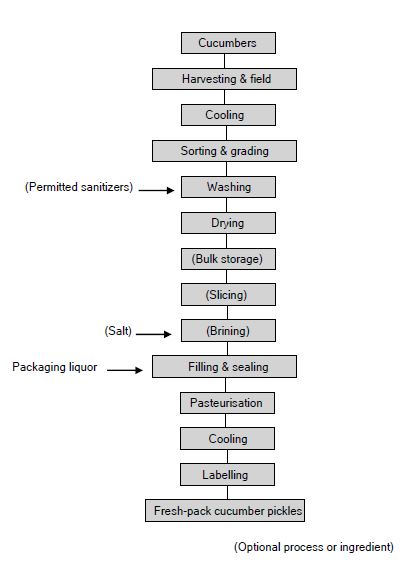

Process description

Harvesting of cucumbers

Cucumbers can be harvested at a range of developmental stages, but it is generally picked at an immature stage before the seeds are fully enlarged and hard. Fruit size is an important factor that determines the harvesting date and varies according to the specifications of the buyer and the specific cultivar.

Cucumbers are harvested by hand at regular intervals to reduce the chance of old cucumbers remaining on the vine, since this will decrease young cucumber production.

The cucumbers should be cut, twisted, or snapped from the vine. Pulling will damage the vine and can bruise the fruit. The cucumbers are placed in plastic crates and transported to the storage/packaging site as quickly as possible.

As labour costs keep on escalating, increased attention is being paid to mechanical harvesting and harvesting aids. Machine harvesting is possible for certain cucumber cultivars, but results in lower yields.

Selective hand picking is very labour intensive but simultaneously performs the task of field sorting as well. Fruit with signs of decay, insect infestation, yellowing and malformations are discarded in the field.

Fresh-pack dill pickles. (Image source: lakesidepacking.com)

Cooling of cucumbers

Cucumbers should be cooled as soon as possible after harvest to remove the field heat and reduce the respiration rate of the fruit. This is performed by hydro-cooling or forced-air cooling. In the absence of sophisticated cooling equipment, the cucumbers are drenched in cool water in large tanks or barrels. Hydro-cooling can reduce the fruit temperature from 24 °C to 13 °C in about 15 minutes using water at 4 °C.

Sorting and grading of pickling cucumbers

The specifications for sorting and grading vary greatly according to the market and/or processor requirements. Uniformity of size, colour and shape is especially important for mechanised processing.

The cucumbers are inspected upon arrival at the storage/processing site and any damaged, infested, rotten or off-colour fruit are removed along with any remaining blossoms. Culls also include curved, pointed, and con-stricted fruits.

Pickling cucumbers must be size graded. Size grading is particularly important when the food product is to be heated or cooled as the rate of heat transfer is partly determined by the size of the individual pieces. Uniformly sized food product also makes a better display and is preferred by consumers. Size grading is performed by diverging roll bars according to the diameter of the fruit. Grades vary according to the buyer’s specifications.

Example of processing grades:

Washing of cucumbers

The cucumbers are washed with high-pressure water sprays and soft rotating brushes to ensure maximum cleaning with minimum bruising. To conserve natural resources, the wash water is often recirculated. The recirculated water picks up dirt, trash, and disease-causing organisms. If the necessary steps are not taken to prevent their spread, these organisms can infect all the produce subsequently processed.

Always use potable water to clean any food product. Potable water is defined as water free from suspended matter and from substances that could be deleterious to the products or harmful to health. In addition, the water must be treated by flocculation, filtration, chlorination, or other accept-able processes to ensure compliance with the following microbiological requirements:

Washing without sanitising the water has the potential to cause greater post-harvest losses due to the easy spread and infiltration of spoilage organisms through water. The correct use of permitted sanitisers greatly reduces surface microbial loads that could lead to post-harvest infection and premature spoilage. The exposure time necessary for effective sanitising varies according to the sanitiser used. Make sure it is used according to specifications and for the minimum time necessary to gain the desired effect. Take note that chlorination as a means of sanitising could lead to surface bleaching of the product. Various sanitisers are pH sensitive, and proper testing of the water should be done to maximise effectiveness of such sanitisers.

Drying of washed cucumbers

Proper drying of the cucumbers should follow washing and sanitising. The cucumbers are allowed to drain and are then further dried with fans.

Bulk storage of cucumbers prior to packaging/processing (optional)

Although cucumbers are mostly processed or packed within 24 to 36 hours, it can be successfully stored. Bulk storage at the plant or in transport containers requires the following conditions:

Cucumbers can be successfully stored for 10 to 14 days under ideal conditions. Rapid cooling is important, but take note that cucumbers are sensitive to temperatures below 10 °C. Symptoms of chilling injury include pitting, tissue collapse and localised softening.

Cucumbers can wilt and shrivel very easily under dry conditions. For this reason, waxing is advised prior to long term storage. Cucumbers are highly sensitive to ethylene (1 to 5 ppm) during storage, resulting in rapid yellowing of the fruit. It is therefore not compatible for mixed storage with crops that produce high levels of thylene such as apples, tomatoes, melons, and bananas.

Cucumbers benefit from controlled atmosphere conditions and although a few days may be added to the maximum storage life under ideal conditions, it is not in common use. Take note that cucumbers are sensitive to high carbon dioxide conditions. Controlled atmosphere conditions are recommended as 3 to 5% oxygen and 0 to 5% carbon dioxide at 12 °C.

Slicing of cucumbers for pickling (optional)

Small cucumbers and gherkins are usually pickled whole. The larger cucumbers are sliced according to the buyer’s specification. Manually operated or automatic cutting equipment can be used.

Brining of cucumbers (optional)

The whole cucumbers and pieces may be brined by immersion in a 10 to 15% salt solution. The brine may be slightly acidified with lactic acid (0,5%). Brining usually lasts overnight, but may be left to continue for 1 to 5 days before the vegetable pieces are removed and rinsed with potable water to reduce the salt content of the vegetable pieces to 5 to 6%.

Filling and sealing of fresh-pack cucumber pickles

The cucumbers or pieces of cucumber are packed tightly into suitable containers that have been properly cleaned. Packaging liquid is prepared from water, salt, vinegar, and spices. Spices are usually in the concentrated extract form and may include ginger, pimento, black pepper, chillies, cloves, and coriander. Other optional additions include green pepper, onion, and dill.

The packaging liquid is poured over the cucumbers, ensuring that all air is displaced between the food particles and leaving a 1 cm head space at the top of the jar. Heating the packaging liquid prior to filling slightly raises the temperature of the product, but is not necessarily effective in decreasing the required heat dosage of the pasteurisation since the majority of the pack consists of the cucumber pieces which are filled at room temperature.

The secret to the preparation of good pickles lies in the development of a desirable flavour and texture consistent with a good balance of flavours. The final equilibrium acidity of the product will depend on the acidity of the pack

Cucumbers ing liquid and on the ratio of cucumber to liquid. The liquid can also be added to the shreds in bulk and allow it to stand for a few days before repacking into jars. This minimises the effect of minor variations in cucumber-to-liquid ratio on the equilibrium acidity of the finished pack.

The jars are hermetically sealed with self-venting, acid resistant lacquered metal caps capable of forming a vacuum seal. The final acidity of the product should be below pH 4,5 and thus only requires pasteurisation for long term storage.

Fresh-pack cucumber slices. (Image source: westernfamily.com)

Pasteurisation of pickled vegetables

Pasteurisation entails the controlled and limited heating of the pickle in sealed containers that are capable of forming a headspace vacuum upon cooling. It is impossible to give specific time and temperature requirements in a general report such as this, since sufficient pasteurisation depends on the size and dimensions of the container, the starting temperature, the type of equipment used, the type of product, and pH. As a general rule, the point of slowest heating in a mixed pickle with a pH below 4,5 should be held at 71 °C for 15 minutes. However, it is essential to institute the most rapid and efficient heating method possible to ensure that the product is not overheated, resulting in softening of the vegetables and a generally poor-quality product.

Pasteurisation is necessary to ensure a long shelf-life of the product. This is achieved by the heat destruction of spoilage micro-organisms and heat inactivation of most enzymes that cause darkening, softening, clouding, sedimentation, and flavour deterioration in a pickled product. Pasteurisation also removes air in the product, thus minimising oxygen dependant spoilage mechanisms.

Pasteurisation can be performed by various methods and equipment. Batch operations commonly make use of steam cabinets or batch retorts while continuous operations use continuous steam cabinets or hydrostatic retorts. The hydrostatic retort consists of a “U” tube with an enlarged lower section where the pressure is maintained by a column of water at the inlet and outlet (the two arms of the “U”). Hot water fills one of the legs while cold water fills the other. The containers are placed on a chain conveyor and fed into the hydrostatic retort via one of the arms. The containers are progressively heated by hot water rising in the tube.

At the bottom of the inlet tube, the containers are moved into the sterilization section where the temperature is increased from 115 to 121 °C. The containers follow an undulating path through this section to ensure sufficient contact time and temperature exposure. After the required time in the sterilisation section, the containers are transported to the outlet column where they are progressively cooled.

Cooling and drying of pasteurised pickles

Pasteurisation should be followed by rapid cooling. Cooling prevents over-heating that would result in loss of sensory quality. The jars are cooled to below 50 °C with cold water. The first stage of cooling takes place in the cabinet/retort by replacing the hot water with progressively cooler water. Further cooling takes place once the containers have been removed. Alternatively, the containers can be quickly cooled by passing them through misting tunnels.

Cooling of glass jars should be gradual to prevent thermal shock that would result in cracking of the jars. The containers are allowed to dry naturally or are blow-dried with hot air blowers prior to labelling.

Labelling of vegetable products

Product must be correctly labelled according to the requirements set out in the Labelling and Advertising Regulation R2034/1993.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.