Pickled beetroot is skinned, sliced and cooked beetroot packed and preserved in vinegar, a little salt, with or without sweetener and spices. The product is sealed in glass jars and pasteurised to ensure a long, stable shelf life. Baby beets may be pickled whole.

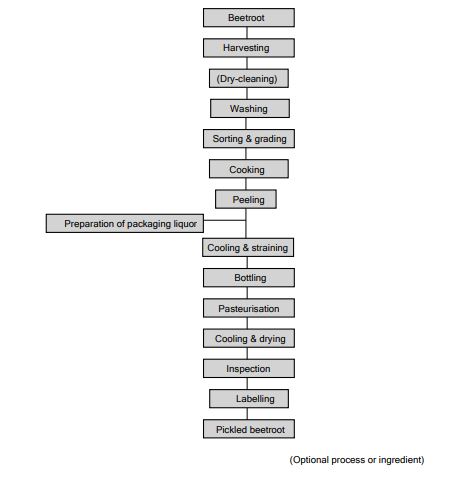

Process description

Harvesting

Commercially grown beets are harvested by means of a mechanical beet harvester that cuts the soil below the root tip, thus loosening the soil for easy lifting. The leaves and excess soil are removed in the field to reduce waste loads on the processing site. Care must be taken to leave a short stalk behind to minimise the leaching of the pigment. The beetroot is taken directly to the processing site or kept at temperatures of 1 °C and relative humidity of 90%. Fresh beetroot yields a superior product since storage leads to a reduction of sugar levels and textural changes.

Dry-cleaning (optional)

Root crops such as beetroot are covered with soil that needs to be removed. The harvested beets can be dry-cleaned by tumbling them in a slightly inclined rotary screen or slotted drum to loosen and separate dry dirt. Dry cleaning is an optional process but reduces the load of the washer. It is only effective if the adhering soil and dirt is dry.

Washing

The beetroot is first soaked whole by being conveyed on a carrier belt submerged in a water tank. Soaking aids the removal of stubborn dirt, and reduces the load of soil in the wastewater to the washer. The beets are then tumbled through a rotary brush washer, followed by rinsing in a rod washer.

Sorting and grading

The washed beetroot is sorted and inspected prior to further processing. Any infected, rotten or badly damaged beetroots are removed manually from the sorting belt. Sizing can be done manually or mechanically by roller graders. Uniformity of size is an important factor if heat processing such as blanching or cooking is performed.

Inspection of beets prior to processing. (Image Source: 4.bp.blogspot.com)

Cooking of beetroot for pickles

Beetroot differs from all other forms of pickled vegetables in that it is cooked and not just blanched prior to pickling. Cooking time and temperature depend on the size and age of the beetroot and the equipment used, but generally between 1 and 2 hours at 95 to 100 °C is required to produce a tender product.

Cooking can be performed by boiling in salted water or by steaming. Each method has its advantages and disadvantages to consider. Batch operations are more common than continuous operations due to the long time required for cooking and the cost of continuous equipment with the desired capacity.

Peeling the cooked beetroot

The beetroot is peeled after it emerges from the cooker. The hot beets are peeled using abrasive peelers. The peeled beets are left to cool in the packing liquid before slicing.

Preparation of packaging liquid

The packaging liquid is prepared from natural malt vinegar to which 2% salt (by weight of the beetroot) has been added. If salt was added previously in the cooking water, it is omitted in the packaging liquid. The addition of pimento for additional flavour is optional. The addition of sweetener in the form of granular sugar, glucose syrup or artificial sweetener is also optional, depending on the age and sweetness of the beetroot and customer preference. Artificial sweeteners are useful in creating diabetic products. The quantity of sweetener to be added is judged according to taste. The addition of sweetener should be declared on the packaging label.

Pickled baby beets. (Image Source: i.telegraph.co.uk)

Cooling the peeled beet

Cooling is necessary prior to slicing to reduce the chance of breaking and fragmenting the hot cooked beets. Rapid cooling is desirable to save time and prevent loss of colour through oxidation, and to reduce the risk of fermentation.

The beetroot is cooled by immersing it in the packaging liquid. The liquid thus serves the dual purpose of cooling medium and preserving during packaging. The cooled beets are removed, drained and passed on to the slicing equipment. The liquid is strained to remove any bits of beetroot, and saved for packaging.

Slicing

Slicing involves cutting a product at a specific angle to produce pieces with equal thickness. The larger sized beetroot are generally cut into smaller pieces. Slices in the order of 5 mm thick are popular for pickling. Uniformity of size is important to ensure an even uptake of acid during storage. Crinkle-cut slices have become quite popular recently. A wide variety of vegetable slicing equipment is available in a wide range of sizes and capacities, depending in the output required.

Bottling of pickled beetroot

Bottling involves preserving and sealing the product in a glass bottle. The whole baby beetroot or sliced beetroot pieces are filled into suitable glass jars and topped with the packaging liquid. The ration of pieces to liquid varies, but a reasonable ration to aim for it 70% slices and 30% liquid (after pasteurisation) as this would result in a final overall acidity of approximately 1,6% and salt concentration of 0,6%. It is important that all the pieces should be completely covered with the liquid. A headspace of 1/8 the volume is left at the top of the jar. The jars are sealed hermetically with self-venting, acid-resistant lacquered metal screw caps capable of forming a vacuum seal.

Pasteurisation

Pasteurisation is a mild heat treatment that destroys all vegetative pathogens and heat sensitive enzymes. Pasteurisation thus improves the keeping quality of the product. Pasteurisation of pickled beetroot entails the controlled and limited heating of the product in a sealed container that is capable of forming a headspace vacuum upon cooling. It is impossible to give specific time and temperature requirements in a general report such as this, since sufficient pasteurisation depends on the size and dimensions of the container, the starting temperature, the type of equipment used, the type of product and the pH. As a general rule, the point of slowest heating in pickled beetroot should be held at 74 °C for at least 25 minutes.

In the case of beetroot, it is not essential to use the most rapid and efficient heating (and cooling) method possible as is the case with other pickled products, since the product has been cooked and a soft texture is desirable. Pasteurisation extends the shelf life of the product by destroying spoilage micro-organisms and heat inactivation of most enzymes that cause darkening, softening, clouding, sedimentation and flavour deterioration. Pasteurisation also removes air in the product, thus minimizing oxygen-dependant spoilage mechanisms.

Pasteurisation can be performed by various methods and equipment. Batch steam cabinets or batch retorts are commonly used for pickled beetroot. The jars are placed in the batch pasteuriser. The temperature is slowly raised to 82 °C over a period of 1 hour, and held at this temperature for the required time. The jars are then removed and allowed to cool. Although continuous retorts can be used, it is very costly due to the large capacity needed for such long, slow heat treatments. Glass jars are currently being replaced by retort pouches. This greatly affects the required processing parameters such as time and temperature required for pasteurisation.

Pickled, sliced beetroot. (Image Source: hostedmedia.reimanpub.com)

Cooling and drying of bottled beetroot

Cooling should follow pasteurisation. The first stage of cooling takes place in the steam cabinet or retort by replacing the hot water with cold water. Further cooling takes place when the containers have been removed. Alternatively, the containers can be quickly cooled by passing them through misting tunnels. Cooling of glass jars should be gradual to prevent thermal shock that would result in cracking of the jars. The cooling water also removes traces of packaging liquid from the outside surfaces of the jar. The jars are then allowed to dry naturally or blow-dried with hot-air fans prior to labelling.

Inspection of the jars

The jars are labelled with pre-printed labels that contain all the necessary information and coding as prescribed by law.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.