Asparagus is preserved by the addition of salt and acid in a suitable container that may or may not be pasteurised. Asparagus is usually pickled as whole spears, alone or with the addition of other minor ingredients.

Spices can also be used. The spices are usually in concentrated extract form and may include ginger, pimento, black pepper, chillies, cloves, and coriander.

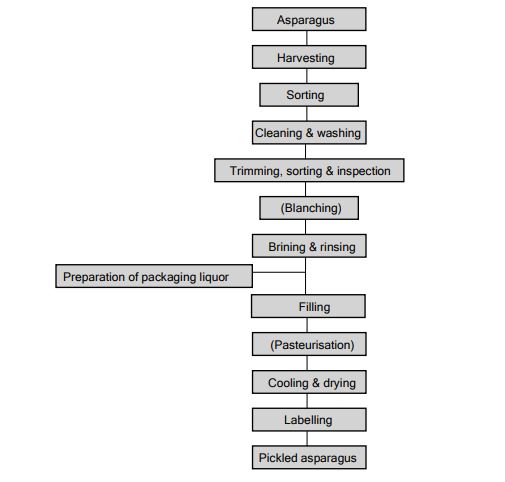

Process description

- Harvesting of asparagus

Harvesting season lasts for 2 to 3 months as the stems emerge in spring. Asparagus are harvested by hand when the correct size and colour has been achieved. This is done by cutting the stem with a sharp knife 3 to 5 cm below the soil surface at a length of approximately 20 cm. Asparagus is transported in an upright position from the field to processing plants as quickly as possible because it soon becomes tough and loses its sweetness. Once the harvesting season is over, the stems are allowed to grow to nourish the underground rhizomes for the next year’s crop. - Sorting

The stalks are spread on flat tables where the loose debris such as sticks and stones, are removed. Any damaged, shrunken or broken stalks are also removed. - Cleaning and washing

The product is washed in large water baths filled with potable water to remove all unwanted soil, dirt, or plant rests adhering to the surface of the product. The wash water must be regularly changed to minimise the chance of any contamination spreading. The water may be still or agitated. A high-pressure water spray can be used to agitate the water to ensure that all surfaces are cleaned. The stalks are then stored in cold water tanks until processing begins. - Trimming, sorting, and inspection

Trimming is the deliberate removal of unwanted or unfit fractions of a food product while sorting is done to select the best suitable raw materials for manufacturing the value-added end product. Any damaged or immature sections must be removed. The quality of the product and adherence to pre-set quality standards (colour, shape, and size) must be controlled by careful inspection. - Blanching (optional)

Blanching is a short heating process, immersion in hot or boiling water or steam, whereby food products are heated to a certain temperature that is high enough to inactivate the enzymes responsible for undesirable changes in colour and flavour. Blanching must be done as soon as possible after preparation and immediately before processing. Enzymes start to break down tissues after harvesting and these waste products can be an ideal growth medium for micro-organisms, which may change the taste and flavour of the product – both advantageously and disadvantageously. Heat treatment prevents enzymatic and microbiological deterioration by inactivating the enzymes and killing plant tissue.

Pickled asparagus (Image Source: striplings.com)

Blanching also has other advantages:

- Improving the colour of the finished product;

- Improved the texture of the final product;

- Blanching cleans the product and reduces the microbial load of the cells;

- Removal of gasses in the intercellular spaces that could cause oxidation of the product and that could lower the vacuum of the sealed container. The disadvantage of blanching is the loss of nutritive value due to water-soluble vitamins dissolving in the blanching water. This can be contained by a short exposure time. During commercial blanching processes the products are heated as quickly as possible to the required temperature and then cooled as quickly as possible to minimise the softening of the tissue and loss of nutrients.

Water blanching: This is the traditional form of blanching where the product is kept in warm water (60 to 85 °C for 2 to 5 minutes) for the required time and then cooled. Retorts can be used. Some solutes leach from the product into the scald liquor, which should be allowed to build up because this minimises the leaching losses.

Reel blanchers/rotary water blancher: This is one of the simplest blanchers. It consists of a screw conveyor moving through a trough filled with hot water, heated by steam coils or direct steam injection, contained within a perforated rotating cylinder enclosed in a cylindrical shell. The speed of the conveyor and the temperature of the water controls the retention time in the warm water as well as the cooling of the product; two blanchers can also be used in series.

Water spray blancher: This consists of a three-stage blancher where the hottest water is used in the middle stage, collected and re-sprayed towards both ends of the blancher – material is warmed towards the centre and then progressively cooled.

Tubular blancher: The product is conveyed through a long tube for a specified time by pumped water, heated by steam injection. Cooling occurs naturally by evaporation and the product is washed in potable water to reduce the microbial contamination and to remove concentrated blancher liquid.

Steam blanching: The advantage of this process is the decrease in the leaching of soluble from the vegetables with increased retention of nutrients. The use of steam blanchers enhances storage life of the final product as there is no need for handling between blanching and subsequent phases. The steam blancher consists of a wire belt, moving through a steam-box or a sealed steam tunnel, which is heated by steam, followed by a deep layer holding zone and a cooling zone.

A helical screw can also convey the heaped vegetable pieces along a covered trough into which steam is injected through perforation on the wall and the hollow screw shaft. Individual quick blanching is a variation on steam blanchers where a thin layer of the product spread on a wire belt moves through a steam box. The product is exposed to sufficient heat to inactivate the enzymes penetrating halfway through the product. The product is then put on a slow moving belt and allowed to reach equilibrium until all parts have received the same heat treatment.

Vacuum steam blanching: End-over-end conical double-jacketed cookers are used. The products are loaded into the cooker and slowly rotated. The pressure is lowered to 10 kPa. The vacuum is broken with saturated steam and atmospheric pressure is applied for one minute. The product is then cooled by lowering the pressure in the container. The advantage of this method is the rapid heating of the product, resulting in a firmer texture. This is a very efficient and waste-effective process.

Microwave blanching: Heat for blanching is generated within the food by subjecting it to high-frequency radiation. There is no leaching of solutes and flavour and nutritive losses are kept to a minimum. This process however has a high initial cost.

Brining

Brining is the addition of dry salt or a salt solution, usually sodium chloride, to food products. The asparagus can be packed directly into a brine with a 8 to 13% salt concentration. The brine may be slightly acidified with lactic acid. The asparagus should be covered with brine and is left overnight. The brine is then removed by draining. Draining aims at removing excess free moisture from a product by gravitational force to obtain partial drying of the product surface.

Rinsing

The salt content of the final product will be too high if the asparagus are packed directly into the acid liquor. It can be briefly rinsed in water and allowed to drain thoroughly.

Filling of pickled asparagus

The asparagus is packed into suitable containers (retail containers) with a packaging liquor. The packing liquor is made from natural or distilled malt vinegar, spirit vinegar, acetic acid or any desired combination according the final product requirements. Spices can also be added. The spices are usually in concentrated extract form and may include ginger, pimento, black pepper, chillies, cloves, and coriander. The final acidity of the product will depend on the acidity of the packing liquor and on the ration of asparagus to liquor. The liquor can also be added to the asparagus in bulk and allowed to stand for a few days before repacking into jars. This minimises the effect of minor variations in asparagus-to-liquor ration on the equilibrium acidity of the finished pack. The asparagus may be kept tightly covered under refrigerated conditions for several months.

Pasteurisation (Optional)

The product may be pasteurised to further extend the storage life by creating a commercial sterile product.

A commercially sterilised product is a product:

- That is processed in such a way as to reduce the number or activity (or both) of viable micro-organisms to such as extent that none are detectable, and

- In which no spoilage or toxicity of microbial origin is detectable under normal, non-refrigerated conditions of storage, distribution, and handling. Pasteurised products are products which are heat treated in a container to a minimum centre temperature of 66 °C for a specified time. Pasteurisation is not often performed as it tends to soften the asparagus. Sulphur dioxide (preservative) can be used close topping up with liquor so as to minimise the volume of the headspace.

Effective hermetically sealed closure and optional vacuumisation during capping will overcome any problems experienced. In some instances, the firm texture is not as important and low acid pasteurised packs, which may include apple or onion, are used. The time of exposure needed to destroy spoilage organisms and pathogens is dependant on the type of product, container size, and type of retort. In acidic foods retorts may be vertical or horisontal. Horisontal retorts are easier to load and unload. The retort is closed and steam is pumped into the closed container. The time/ temperature combination depends on the processing time/temperature required.

Cooling

After heating, the product is cooled, first in the retort when cold water is used to replace the hot water, and then the product is removed from the retort and allowed to cool further.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.