The agricultural sector has always been a challenging industry to work in, with farmers having to deal with harsh weather conditions and often needing to rely on heavy machinery to get the job done.

Equipment such as pumps, valves, and storage tanks are subjected to abrasive materials that can cause them to wear out quickly, leading to costly repairs and downtime. This is where Carl Hamm and SICcast® come in, with their innovative solutions that can help farmers improve the efficiency and durability of their equipment.

Carl Hamm and the partnership with SICcast®

Carl Hamm is a leading company in the field of pumping systems and equipment, known for providing highquality products that can withstand the most challenging applications. SICcast® is a company that specialises in the production of wear-resistant materials for heavy-duty industries, including the agricultural sector. The partnership between these two companies has led to the development of a range of parts that are designed to withstand the harsh conditions of the agricultural sector, providing farmers with a reliable and cost-effective solution for their needs. SICcast® products are made from a silicon carbide material that has been specifically designed to withstand erosive corrosion, making it ideal for use in harsh and demanding conditions where metal parts would quickly wear out.

The farming industry can greatly benefit from SICcast® as it relies heavily on pumps, valves, and other equipment that are subjected to abrasive materials such as soil, sand, and fertilisers. Traditional metal parts tend to wear out quickly in such conditions, leading to costly replacements and downtime. SICcast® parts are designed to be resistant to both corrosion and abrasion, making them a highly suitable replacement for traditional metal parts. They are made from a special mixture of silicon carbide and epoxy resin that is cast into precision moulds under vacuum, resulting in a material that is extremely wear-resistant, temperature-insensitive, and shockproof.

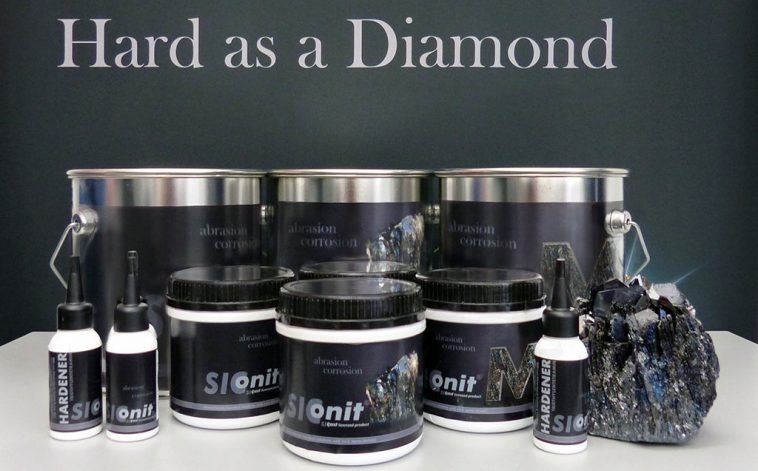

Carl Hamm protects your machinery with SIConit®

SIConit® is another silicon carbide coating compound that has been designed for repairing and protecting metallic surfaces exposed to abrasion, corrosion, and acids with a pH value of 0 to 12. With its high silicon carbide content, SIConit® can be used in extremely abrasive operational conditions where complex and costly repairs are typically required. The compound can either be used to completely rebuild worn metal surfaces or be used as a preventative coating, often outperforming the original metal in terms of abrasive stability. In the agricultural sector, SIConit® has a variety of potential uses. One of the main uses could be in the repair and protection of farm equipment such as ploughs, cultivators, and other machinery that experience high levels of abrasion and corrosion.

These pieces of equipment often come into contact with soil, rocks, and other materials that can quickly wear them down, leading to costly repairs and downtime. By coating these pieces of equipment with a highly wear-resistant material such as SIConit®, farmers could reduce the need for frequent repairs and improve overall productivity. Another potential use for SIConit® in agriculture is in the protection of storage tanks and silos. These structures are often used to store chemicals, fertilisers, and other materials that can be highly corrosive, leading to costly repairs and potentially dangerous leaks. By coating the interiors of these structures with SIConit®, farmers could protect them from the corrosive effects of the stored materials, extending their lifespan and improving safety on the farm.

SIConit® could also be used in the production of irrigation systems, which often rely on metal components that can be prone to corrosion and wear. By coating these components with SIConit®, farmers could improve their durability and reduce the need for costly replacements and repairs. Overall, the use of SIConit® in agriculture could lead to significant cost savings and productivity improvements for farmers. By protecting equipment and structures from the effects of abrasion and corrosion, farmers could reduce downtime and maintenance costs, allowing them to focus on their core operations.

As with any new technology, there may be a learning curve associated with the use of SIConit®, but with proper training and support, it can become an essential tool for farmers looking to improve their operations.

For more information on the products and services that Carl Hamm PPS provides, contact Desmond Enslin on (+27) 83 556 4642 or send an e-mail to desmond@carlhamm.co.za. Visit our the website at www.carl-hamm.co.za.