A story is emerging of how one timber processing company in Ivory Coast is building a blueprint for Africa to use its timber resources better to create more opportunities and ensure increased sustainability.

South Central Ivory Coast is the home of Sustainable Teak Exports (STE).

The company is owned and operated by Hasan Mshawrab, a remarkable young Ivorian of Lebanese descent.

Hasan initially only exported round logs from Ivory Coast without adding any value to the logs. The Ivorian government’s restrictions on log exports forced a rethink of his business model.

The restrictions dried up his logs supplies and he also realised that he could be earning more money if he added value to the logs that was exported in raw form until then.

“I realised that the Ivory Coast, like many other African countries, was losing money with log exports. If I could produce sawn timber and then manufacture furniture from it, I could dictate the price I want, instead of the low prices that I got for logs.

“The Ivory Coast’s economy would also improve; manufacturing can start and job opportunities could be created that young Ivorian’s like me could use to improve our lives and create a better future for our families and others

“I also know that people will not protect forests if they have no value – if I could build a successful business using Ivorian timber, others like me will treasure forests more and protect them,” Hasan says.

Hasan Mshawrab, owner of Sustainable Teak Exports and visionary sawmiller from the Ivory Coast.

Building a business with Wood-Mizer

The First step to realizing his dream of an integrated timber production company saw Hasan investing in sawmilling and blade maintenance equipment from Wood-Mizer.

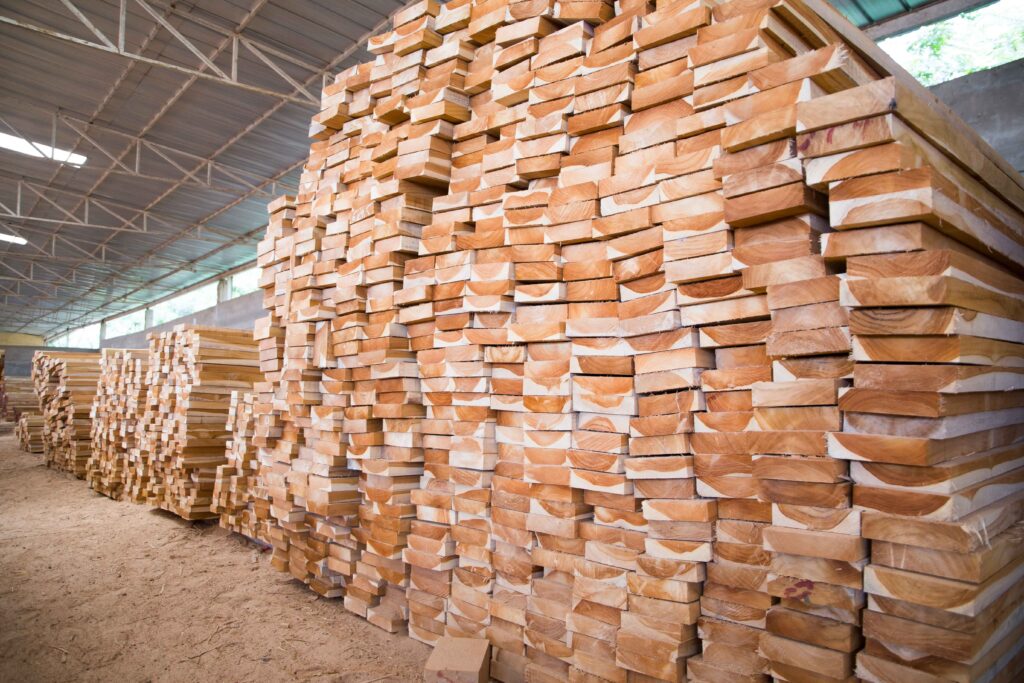

STE now has four Wood-Mizer LX100 sawmills that are used to produce sawn timber from the sustainably harvested teak logs that are sourced from the Ivory Coast’s Timber Management Agency Sodefor.

Bespoke solid teak furniture from STE waiting for surface treatment before being exported. The finished pieces earn far higher profits than logs that are exported.

STE’s two-head Wood-Mizer HR500 resaw and EG300 Edger cut the sideboards that were formerly thrown away into valuable timber. “We realised that we wasted a lot of timber, so with our recovery equipment from Wood-Mizer, we now have more timber that we can sell,” Hasan says.

Sawn timber from the sawmill and bespoke furniture items from STE’s manufacturing arm, are now exported to markets in Asia, Europe and the Middle East. Kitchen, bedroom items and doors supply local markets that formally relied on expensive imports.

Sawn teak from sustainably managed plantations and that are exported or used in Ivory Coast, have improved STE’s margins considerably and also allows for downstream manufacturing to start.

Saw maintenance equipment from Wood-Mizer allows STE to re-sharpen and set their own bandsaw blades that are used on the sawmills.

“Our saw sharpening division is very important,” Hasan says. “We no longer have to rely on outside suppliers that are not reliable for sharpening blades. We now control the quality of the process and the costs.”

STE’s showroom facilities in the Ivory Coast’s capital Abidjan, adds further value to STE’s operations with bespoke furniture items sold directly to customers from across Ivory Coast. The facility also doubles as STE’s design and admin headquarters.

With Wood-Mizer’s saw maintenance equipment, STE always has sharp blades. A ready supply of sharp blades improves productivity, cut quality and volumes.

Final Take

Africa has tremendous potential to harness it timber assets for growth.

Cheap log exports only generate a fraction of the potential value that the continent’s timber resources hold, and that can fuel future economic growth. There is also little or no incentive to protect a resource that is not considered valuable.

Sawmillers like Hasan Mshawrab represents a new generation of sawmillers from Africa.

They recognise that Africa’s timber resources are hopelessly undervalued. They also understand the link between timber, economic growth and the sustainable management of the resource.

“When we keep the timber in Africa, unlock the full value that it holds for benefit of Africa, and preserve the resource, then we have a business for many generations, Hasan concludes.

STE has up to 50 permanent and 20 part-time employees. Local sawmilling and manufacturing boost local economies by creating employment that creates a better life for more people.