The efficient application of agricultural sprays is essential for effective crop protection and desired outcomes. Hydraulic nozzles used for spray applications produce a range of droplet sizes and velocities, and these variations can significantly impact the effectiveness of the spray.

The ability to quickly and simply describe the quality of spray produced by a nozzle is essential for better understanding its impact on the efficacy of application and the safety of using different sizes and types of nozzles at various pressures.

Measuring the droplet size spectrum of a spray can be accomplished using various measuring systems, such as laser-based techniques (laser diffraction, droplet imaging, phase Doppler analysis). These methods provide valuable data on the size distribution of droplets in the spray.

One common way to present the results of droplet size measurements is through a cumulative volume curve. This curve represents the cumulative volume of spray contained within a range of droplet size classes, each represented by an average droplet diameter. The curve provides a clear visualisation of the distribution of droplet sizes in the spray and allows users to understand the dominant droplet size range and the spread of droplet sizes present.

By analyzing the cumulative volume curve, users can assess important aspects of the spray, including:

- Droplet Size Range: The curve shows the range of droplet sizes present in the spray, from the smallest to the largest droplets.

- DV0.1: is a value where 10% of the total volume of liquid sprayed is made up of droplets with diameters smaller or equal to this value. For example, if the DV0.1 is listed as 100 μm, this means that only 10% of the volume of the spray is contained in droplets smaller than 100 μm (microns)*. The other 90% of the volume of the spray is contained in droplets larger than 100 μm.

- DV0.5, also known as Volume Median Droplet Size – VMD: The point on the curve where 50% of the cumulative spray volume is reached represents the median droplet size, a critical value for assessing spray drift potential and efficacy. For example, if the VMD is listed as 250 μm, this means that 50% of the volume of the spray is in droplets both larger and smaller than 250 μm.

- DV0.9: is a value where 90% of the total volume of liquid sprayed is made up of droplets with diameters smaller or equal to this value. For example, if the DV0.9 is listed as 500 μm, this means that 90% of the volume of the spray is contained in droplets 500 μm or smaller. Only 10% of the volume is contained in droplets larger than 500 xn-

- Driftable Fines: the percentage of droplets with a diameter smaller than 150 μm in an application volume. Spray drift occurs when these fine droplets are carried away from the intended target area by wind or other factors, leading to unintended deposition on nearby sensitive crops, water bodies, or non-target

- Droplet Size Uniformity: The steepness or slope of the curve indicates the uniformity of droplet sizes in the spray. A steeper curve suggests a more uniform droplet size distribution, which is generally desirable for effective and consistent spray co

- Relative Span (RS): the parameter that indicates the droplet size uniformity distribution produced by a tip. The lower the RS value, the more homogeneous is the spray droplet sp

- Fine vs. Coarse Droplets: The curve’s shape can indicate whether the spray contains mostly fine droplets (e.g., good for coverage) or coarse droplets (e.g., reduced drift potential but potentially reduced coverage).

These parameters and techniques have been incorporated within the droplet size classification systems, which follow a strict and concise parameter, which was first created in 1985 in England by the British Crop Protection Council (BCPC).

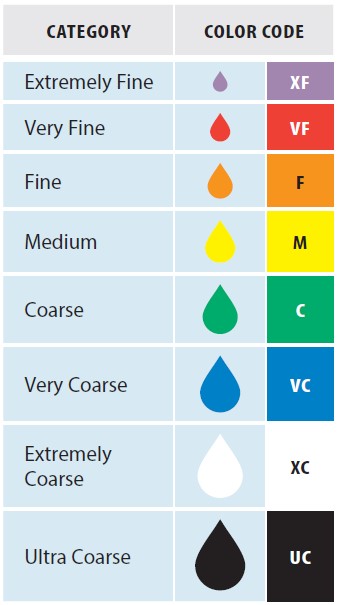

- British Crop Protection Council (BCPC) Classification (1985): This classification system established a series of five droplet size classes – Very Fine (VF), Fine (F), Medium (M), Coarse (C), and Very Coarse (VC).

- ASABE S572 (1999): The American Society of Agricultural and Biological Engineers (ASABE) developed a new standard for droplet size classification known as ASABE S572 in 1999. This standard introduced six droplet size classes: VF (Very Fine), F (Fine), M (Medium), C (Coarse), VC (Very Coarse), and XC (Extra Coarse). The boundaries between these classes were defined using reference spray tips and operating pressures.

- ASABE S572.1 (1999): After the initial release of ASABE S572, two additional droplet-size classes were added in the same year, resulting in a total of eight classes. The additional classes were XF (Extra Fine) and UC (Ultra Coarse).

- ISO 25358 (2018): The International Organization for Standardization (ISO) published the ISO 25358 standard in 2018. This standard updated some of the droplet size classification ranges to better distribute the classification boundaries. Specifically, the changes were made to the C/VC, VC/XC, and XC/UC boundaries. The new droplet size data in TeeJet Technologies Catalog 52 is based on this updated classification standard.

- ASABE S572.3: To align with the ISO 25358 standard, ASABE updated their standard and released ASABE S572.3, reflecting the same droplet size classification as ISO 25358.

Droplet size classifications are in accordance with ISO Standard 25358 at the date of printing, and its standard classification is subject to change.

Check out our new catalogue for more information.

By refining the boundaries between droplet size classes, the new system provides a more accurate representation of droplet size distributions in agricultural sprays. This improved accuracy enables users to make informed decisions regarding nozzle selection and spray application methods, resulting in enhanced spray efficiency and efficacy.

As an active member of the ISO committees, TeeJet Technologies’ adoption of the new droplet size classification system into your nozzles reflects a commitment to staying at the forefront of agricultural spray technology. By incorporating the latest advancements in droplet size measurement and classification, TeeJet demonstrates a dedication to providing cutting-edge and effective solutions to farmers and agricultural professionals.