In this article we share a collection of cross-sectional dam wall designs for different scenarios. We also look at polypropylene as a sealing material.

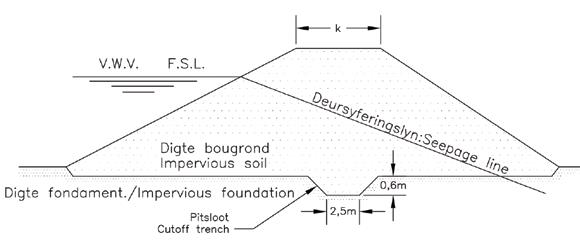

Suitable, uniform impervious building material on an impervious foundation.

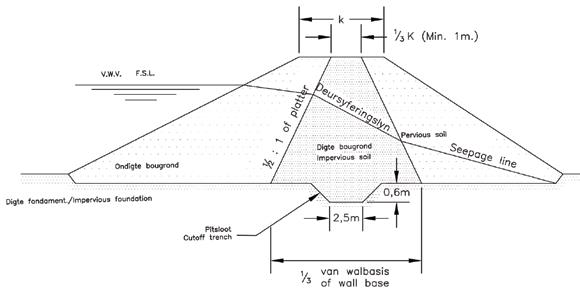

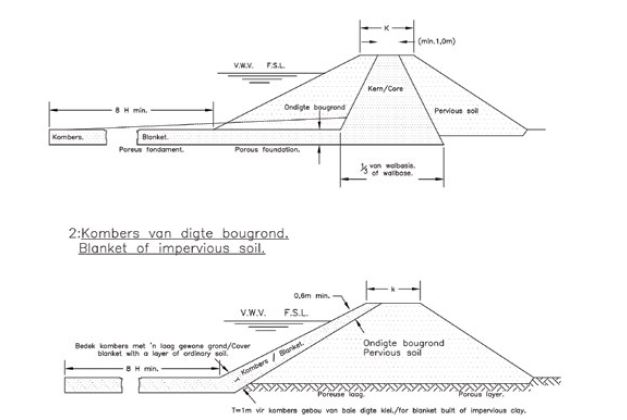

Pervious building material on a limited quantity of impervious building material on an impervious foundation.

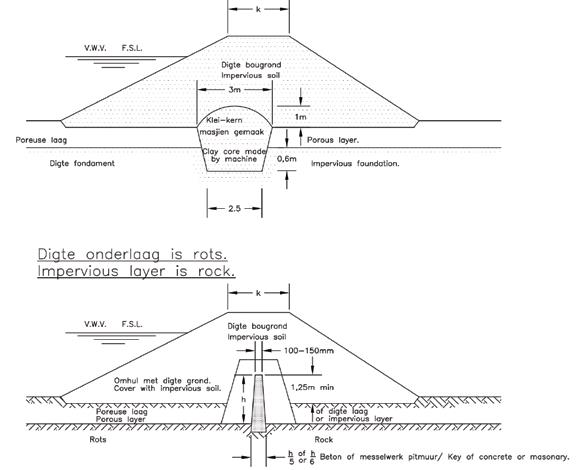

Suitable, uniform impervious building material on a porous foundation layer. Porous layer too thick to be removed economically, impervious under layer is within reasonable depth. Impervious underlayer is clay.

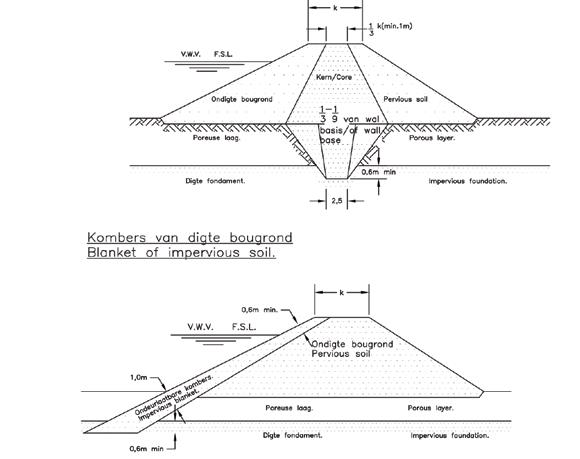

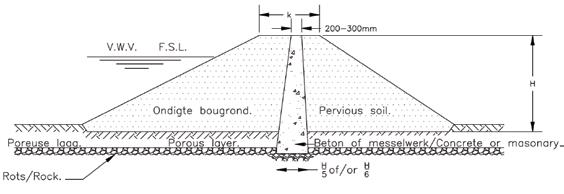

Pervious and a limited quantity of impervious building material available on a pervious foundation layer. Porous layer is thick and impervious within reasonable depth.

Impervious and pervious soil and foundation on considerable depths.

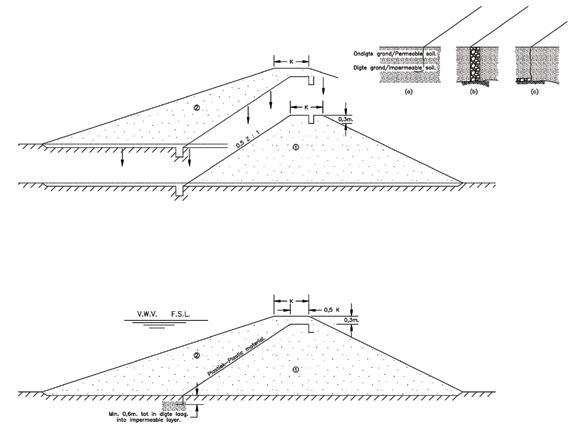

Permeable building material on rock. No or little building soil is available. Danger of damage to wall by rodents and ants.

Sealing with plastic

Polypropylene dam lining

The following procedure will deliver the best results when using plastic as a dam sealer:

- Do the required normal preparation for the base of the wall or as the site may dictate.

- Build portion 1 of the wall according to the prescribed procedures. The water side of the wall is finished smooth with a spade, and hard clots and stones must be removed.

- Dig a trench in the length of the wall at the upstream toe of the wall at least 0,6 m deep in dense foundation or up to the rock foundation. A second trench is made all along the wall.

- The plastic is cut beforehand to the required width and length and rolled up. Place the loose end of the plastic in the trench on the crown of the wall, fill the trench with soil and compact carefully and thoroughly by hand. Roll the plastic down and place the other end in the trench in the base of the wall. The plastic must be put down by its own weight and must not be pulled tight. Although the plastic has a stretch ability of 300%, it can, however, be damaged while replacing the soil with heavy machinery.

- In the case of an earth foundation, the trench is covered and compacted by hand and finally rounded off by tractor. Earthmoving equipment must under no circumstances move on the plastic.

- In case of a rock foundation, a low concrete wall can be built and the plastic can be pasted on to it, or the polypropylene can simply be cast fixed with concrete, in the case of smooth rock.

Sealing with polypropylene.

Published with acknowledgement to the ARC Agricultural Engineering for the use of their manuals. Visit www.arc.agric.za for more information.