Farming should never come to a stop, especially when you have to plough, sow, or harvest at the critical times dictated by nature. Nothing fully describes the disappointment, frustration, and financial impact of a tractor or harvester that breaks down in the middle of the job.

But what if you could foresee and prevent it?

CNH Industrial now offers farmers a solution that, in the company’s opinion, is a revolutionary improvement on proactive support and remote monitoring. The brand new Connect facility was introduced to the media during August with the news that South African customers will be managed from the Isando headquarters’ Connect Centre.

“With the exponential increase in the number of connected machines in the field, the need for advanced technology that efficiently manages these fleets is more important than ever,” reads the statement from CNH Industrial.

For CNH Industrial, it is about giving their valuable customers the technological means and support so that the farmer can complete his work with joy and without headaches.

“We offer support to our customers across the brands they use, including Case IH, New Holland, and Case Construction,” says Jacques Taylor, Managing Director of CNH Industrial South Africa. “At the heart of our connected services is putting the customer first, being proactive, and delivering an excellent customer experience.

“Customers are constantly under pressure to increase their efficiency and productivity, and they look to us as manufacturers to find ways to help them achieve this. Our Connect Centre will enable us and our dealers to act quickly—almost in real time—when farmers have problems and help them get the most out of their equipment,” he explains.

Jacques Taylor, Managing Director of CNH Industrial South Africa, introduced the Connect facility.

The Connect facility works like this:

This facility will serve as the core within a network that will be known as “Connect Rooms” at Case IH dealers and “Intellicentres” at New Holland dealers.

Through continuous monitoring of the performance of the connected machines, the system can prevent any problems that may arise.

Just as you can already see from your mobile phone what is happening with your tractor or harvester in the field, there is now a more comprehensive set of data that is also monitored by the Connect Room staff. These individuals are trained technicians who, together with the software (which uses artificial intelligence), can see in real time exactly what the machines are doing.

Possible problems are pointed out according to severity, from most critical to least critical, so that the technicians can deal with the cases accordingly. From there, possible causes are identified and resolved. In the event of a problem, an immediate warning is sent to the dealer, who takes proactive action to manage and resolve the situation.

There are several ways in which these problems can be proactively dealt with:

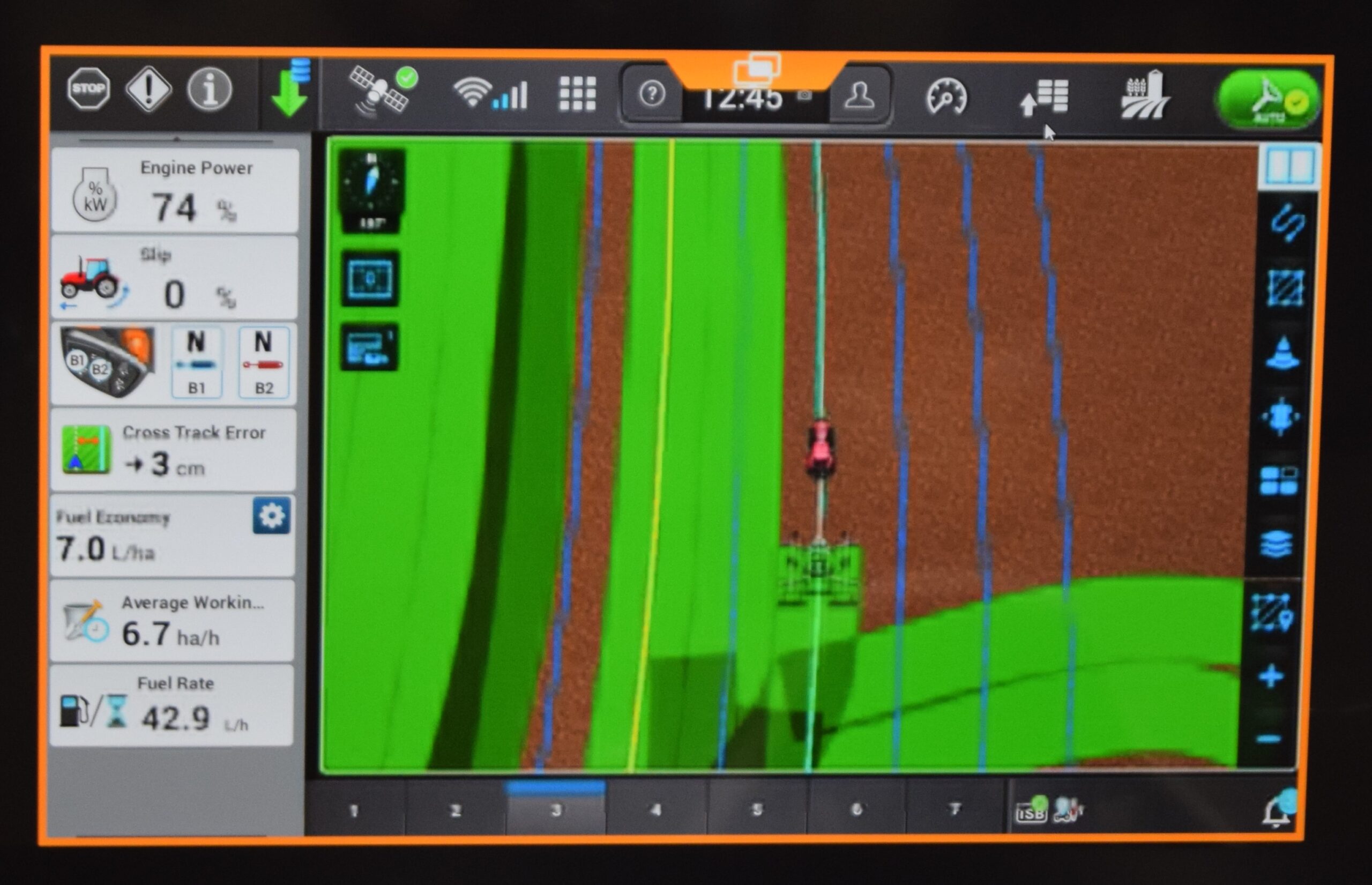

- The technician can provide remote assistance to the farmer by connecting directly to the implement’s screen and guiding the driver to make settings.

- The local dealer or service provider can be contacted to visit the farm with the necessary tools and replacement parts.

- The local dealer or service provider can be contacted to inform the farmer about the problem that can be solved with a maintenance service.

- By identifying any possible problem as soon as possible, farmers and operators benefit because a worn or failing can be corrected or replaced in no time.

It also promotes optimal machine health, which can make parts last longer.

A further advantage for the owner of a fleet is that he or she can be sure of efficient fleet management because the entire fleet is maintained without leaving the farm and preventative maintenance is planned around routine maintenance services.

With the ability to allow technicians to perform remote diagnostics on the customer’s machine from the facility, they can take action without even leaving their desks.

The demonstration showed how a technician can connect to the screen of the tractor from the Connect Room.

The Connect Centre produces reports that provide insight to customers.

Thanks to the new facility, farmers and operators always have important information that enables them to ensure the implement will continue to work hard and efficiently. Three reports are provided:

- The monthly Machine History Report, compiled according to the telemetry and sensor data collected by the connected machine, gives the customer a better understanding of his machine’s usage and operational status and identifies potential problems. This enables customers to ensure the good use and health of the machine, which also protects its residual value.

- The Machine Care Report shows all maintenance, repairs, and inspections in the life of the machine, which ensures the traceability of its entire service history and creates a transparent relationship with the dealer.

- The Operational Report helps the customer ensure that operators are using the machines correctly, efficiently, and safely. With the operating key performance indicator and insights provided by the report, the customer can detect or identify errors in the operator’s use of the machine and determine where there is room for improvement. He can then consult the dealer about customised operator training.

New Holland customers’ facilities will be known as “Intellicentres”. It also uses the same RTK network acquired earlier in 2023.

CNH Industrial demonstrates how the system works

During the launch of the Connect facility, Esmond Coen, Head of Agricultural Solutions at CNH Industrial, gave a demonstration of how a tractor works in a field. It showed how a technician from the Connect Room connects to the tractor’s screen. From there, Esmond indicated how the operator could make corrections under his guidance.

Any customer of CNH Industrial will receive 24/7 supervision. The company aims to make “Connect Rooms” and “Intellicentres” available across its dealer network in 2024.

For more information on this new technology, visit the CNH Industrial website at https://www.cnhindustrial.com/.