It’s one, two, three and your soil is cultivated and planted. Farmers don’t need a separate soil tiller and planter because the Kerneland u-drill 6000 Plus does everything in one.

“The Kverneland u-drill 6000 Plus requires little maintenance and plants accurately,” says Nico Jacobs. He farms with wheat, maize and Lucerne on the farm Karibu outside of Modderrivier.

In addition, Jupidex is the distributor of this useful money and time saving tool, which means the farmer can always count on the best service and advice.

The u-drill 6000 Plus is available in widths of 3,0 and 4,0 m and 6,0m that can fold up to go easily through gates.

With the Kverneland u-drill Plus you do not need anything else.

He prepares the seedbed, levels, sows and fertilises. Among its main features are its perfect seed and fertiliser placement, high performance and the large number of hectares you can cultivate in a day.

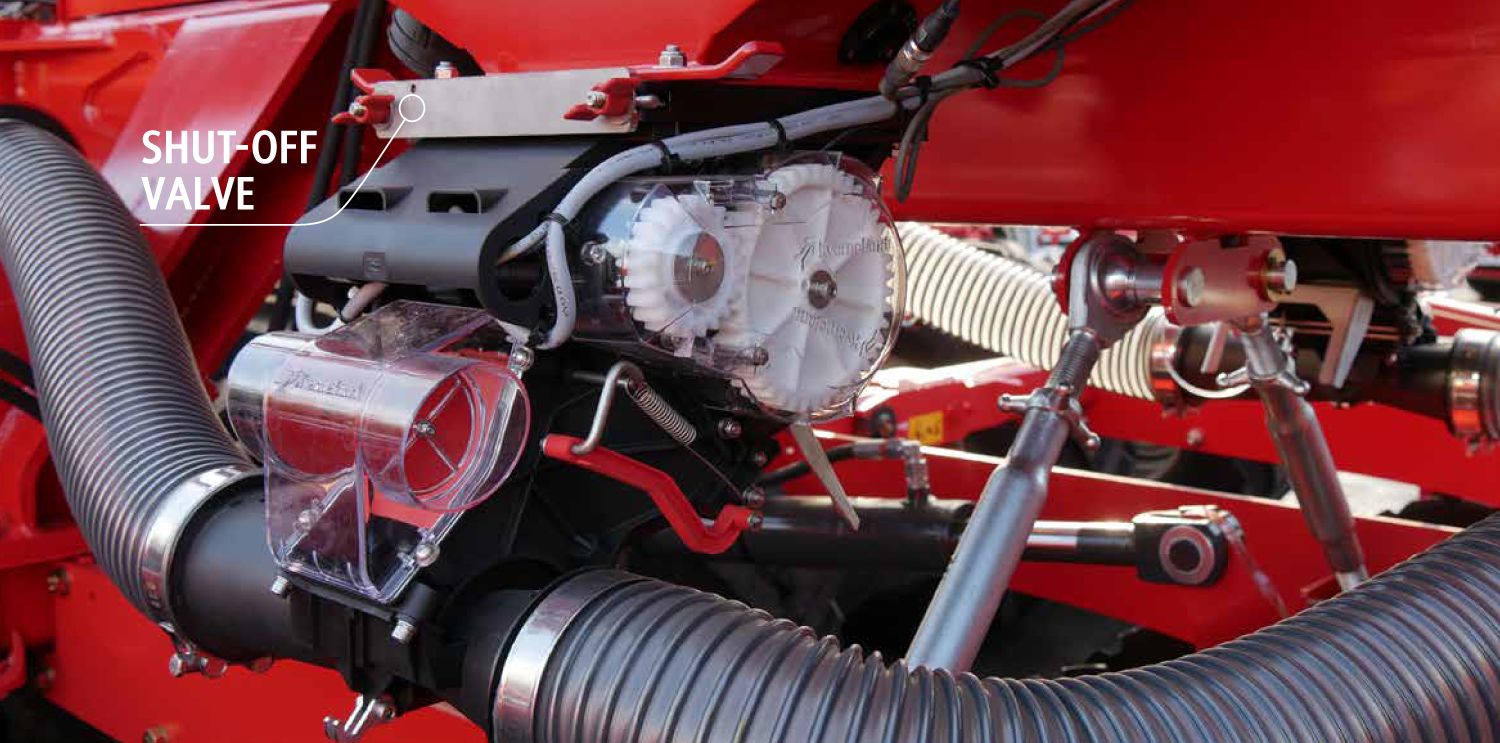

The “plus” stands for the extra feature of the grain and fertiliser version to apply either grain and fertiliser or, alternatively, two different sorts of seeds at the same time. This has been achieved by the divided hopper equipped with two metering devices.

Nico also gives his granular fertiliser through the planter. “It just takes 10 minutes to calibrate the planter and then it plants perfectly accurately,” he says.

“It cannot be easier than that.”

Depending on the working width of this universal trailed seed drill combination, the hopper capacity is either 3000l (3m and 4m) and 4350l (6m). The hopper of the rigid u-drill plus is divided lengthwise and the two metering devices are accordingly positioned on either side. The proportion is 40 : 60.

The Kverneland u-drill plus is able to deliver fertiliser application rates up to 400kg/ha and 15 kph.

“I plant between 30 and 35 hectares per day with a John Deere 8320R tractor of 239kW (320 horsepower). I will say the machine needs at least a tractor of 201 kW (270 horsepower) to tow the planter,” Nico added.

The implement works for you, not you for him. It needs less maintenance.

Nico grease a few parts in the morning. “Jupidex service is great and they always have the parts available to keep all the implements in a working condition.”

ISOBUS is made for easy machine control and efficient farming.

Measure seed precisely and safely with ELDOS’s precise seed measurement.

How does the Kverneland u-drill 6000 Plus works?

Levelling of the soil

For the best possible preparation, the front tyre packer levels the soil, crushes large clods and thus paves the way for the optimum depth control of the following tools. The front tyre packer has a diameter of 800mm. When it is not needed, it can be lifted hydraulically, simply by pushing a button.

Prepare the seedbed

The disc harrow section consists of two rows of aggressively pitched conical discs. Thanks to their conical shape, the cutting angle remains constant. The high rotation speed ensures an excellent cutting quality over the entire working width. Fortunately, this does not happen often, because the disks 55-58HRC (215 kg/mm²) are 5mm thick and hardened for longevity.

The MD disc section consists of two rows of straight-waved discs. The MD disc has been designed for vertical penetration through the flutes. The blade keeps turning, penetrating and cutting even in the most challenging conditions. The seed setting is centrally managed via the ISOBUS terminal ensuring that each seed makes good soil contact and has the best chance of germination and healthy growth. It also ensures that each fertiliser granule ends up in exactly the right place to do its job at its best.

First pack, then seed

For perfect depth control of the coulters and an optimum seed-to-soil contact providing excellent capillary action, the loosened soil is re-compacted by a large tyre packer.

Final touch

Harrowing the soil completes the drilling. S-shaped or finger harrows ensure an optimum covering of the seeds. The working intensity can be set by the stepless pressure adjustment and at three different angles. To prevent damage to the harrow when reversing, it is equipped with an effective reversing device.

The u-drill’s fully automated control makes life even easier for the farmer and operator. With the press of just one button, the operator sets the operation in action: wheels, discs, coulter rod, seed and fertiliser closure, pick-up, so that the operator does not have to remember and do everything manually, but can concentrate on turning neatly and tackling the next track – all of this happens with the help of a single double-directional hydraulic valve to the tractor.

The u-drill 6000 Plus can be seen at Jupidex stand at the NAMPO harvest day, Bothaville (stand B8 + B31).The Jupidex group is dedicated to bring the latest agricultural and also precision technology to farmers.

Visit their website at https://www.jupidex.co.za/ or contact (+27)33-386 3574 for more information.