The most important consideration in Massey Ferguson’s planning is the farmer’s needs. That is why Massey Ferguson strives to balance new technology of the highest quality with the reliable efficiency that farmers have become accustomed to over the years. This is exactly what their Trident range of harvesters offer farmers.

During the recent harvesting challenge presented annually by the Grootpan study group, the MF 9695 Trident harvester came to show its mettle.

“The machine we entered in this race was the MF 9695 class 6 harvester,” says Thomas Wait, Marketing Manager of AGCO.

Technology that ensures power and efficiency in the MF9695

The rotor of the MF9695 is 700 mm in diameter with the characteristic Trident system. This system is designed to ensure even flow through the rotor through 360 degrees of input into the rotor.

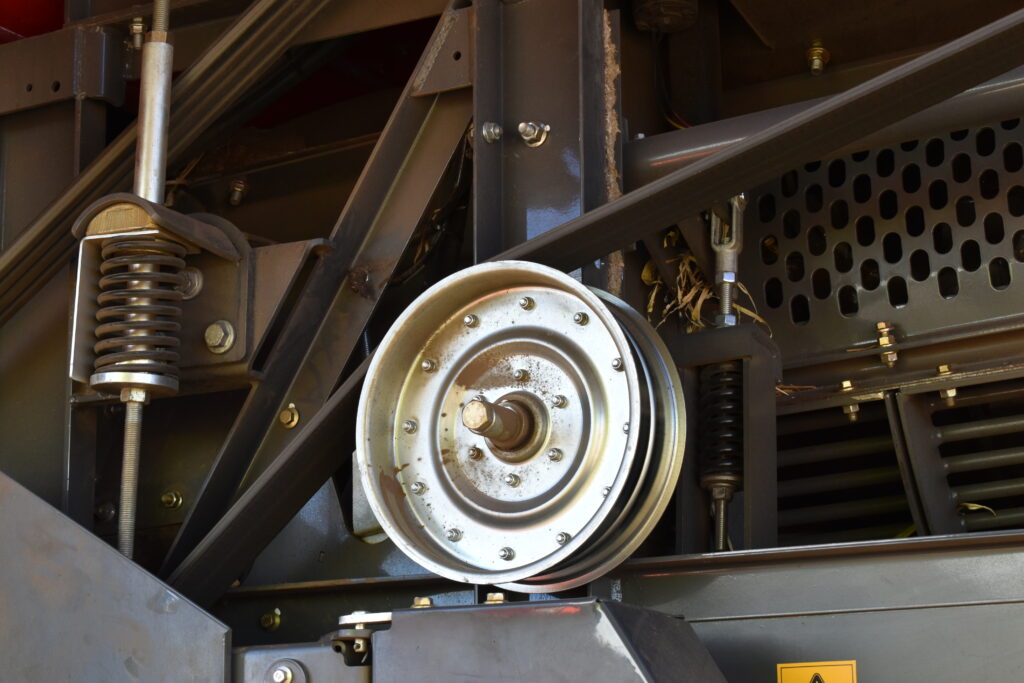

“The concave is attached to the framework with large springs. The reason for that is that when there is a large volume of material moving through the rotor and it gets stuck, then the springs give way and the load falls to the back,” Thomas says. “What makes this machine unique is that the motor and rotor are placed in line with each other,” he explains. “There is also a V-cooling system which means that there are two radiators mounted in a V-shape with a screen at the top. It also has an independent reversing fan which works hydraulically, of course.”

These features give you more power for harvesting.

Thomas moves around the harvester to indicate on the back of the machine: “Because the rotor and motor are in line with each other, this means that the rotor only needs two drive belts for propulsion. It is clearly visible from behind.”

The distinctive V-cooling system has two radiators and a screen at the top.

Simple access to the MF 9695’s engine

On the right side of the machine, it is very easy to access the engine. There is a large flap that opens. From here the operator can service all necessary components of the machine.

The air that the AGCO Power engine draws in through the air filter is extracted from the V-cooling system, which means the air is even cleaner than usual – certainly an important feature in a dusty field where the wind blows the residue around!

The grain tank holds 10 000 litres. The off-loading speed is 88 litres per second.

The springs along the concave are designed to give in when the volume fed to the rotor becomes too high. It then dumps the material to the back.

Inside the MF 9695’s cab

The cab is spacious and gives the operator enough visibility. The thin corner pillars are placed in such a way that they do not disturb the line of sight.

On the right side of the cabin the controls are conveniently located at the right armrest.

All settings can easily be done from there, such as lifting the head or draining the grain from the tank.

“There is also a C2100 screen mounted on the right pillar,” says Thomas. “You can store and send all your crop maps on it. ClimateField view is also possible. All the machine’s adjustments that can be done with the controls can also be done on the touch screen.”

Thomas Wait, Massey Ferguson Marketing Manager.

To locate the MF combine that fits your farm, visit the Massey Ferguson website.