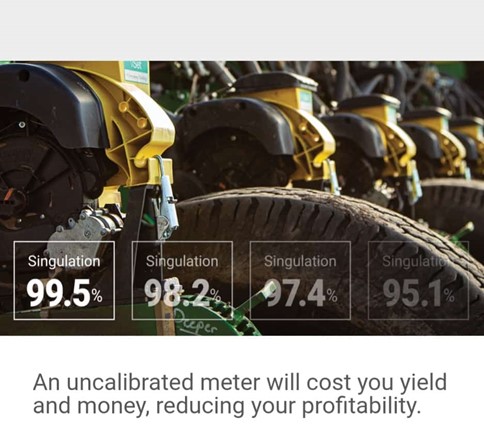

Seed meter calibration:

Over time, seed meters can become inaccurate due to component wear. Meters that no longer measure accurately can lead to double planting or skipped plant spaces, resulting in your plant population not being established as planned or expected, causing significant financial damage in the end.

This is why seed meter calibration is crucial, and if necessary, the replacement of certain components in the seed meter. Ripper Tillage Equipment uses a special seed meter testing machine to test and calibrate the meter. The ideal time to have the meter tested and calibrated is just after the planting season. Do not wait with short notice before the next planting season! We also offer pickup and drop-off services for your seed meters for testing and calibration.

Planter maintenance:

Maintaining planters is essential to ensure that the tools work optimally. If you neglect to service your planter regularly, it can cost you dearly. Here are a few guidelines to follow:

- Row cleaners: The row cleaner is a crucial component that must perform its task properly in front of the row unit. The row cleaner’s bearings should be checked to ensure they can rotate freely, as well as the frame and the bushes to ensure that the seed makes contact only with the ground.

- Parallel arms and bushes: This is a critical item on your row unit that needs to be checked. When the arms or the bushes are worn out, it can cause the row unit not to work optimally and run smoothly. This affects seed spacing and planting depth, affecting emergence and stand. Ripper Tillage Equipment can replace, repair, or upgrade your planter’s parallel units.

- Keeton seed firmer: This useful component ensures that when the seed reaches the seedbed, it is firmly pressed against the bottom of the seedbed, eliminating any air pockets underneath, and ensuring that the seed has full contact with the moist soil. Check the device carefully and make sure it is not worn in a V-shape, as it will then smear or clump. Once you see that your device is worn out, replace it rather than waiting longer. They are available as a standard seed firmer or the Keeton low-stick seed firmer. Both have liquid tubes for application in the seed furrow.

- Seed tube: The seed tube carries the seed from the seed meter into the seed furrow. When the seed tube is worn out, it can cause the seed not to be properly placed in the ground as it should be. The Bull’s Eye seed tube is known for its hardened tungsten carbide tip at the bottom of the discharge, which helps the tube have a longer life and not be quickly damaged by the seed wheels that might scrape against it. Also, pay particular attention to the seed tube guards and do not hesitate to replace them if they are worn out. Ripper Tillage Equipment also has these parts available.

- Disc openers: When these two devices on the row unit are worn out, it affects the seedbed where your seed should fall, which in turn affects emergence and yield. It is important to ensure that before each season, your disc openers are set to the standard diameter according to your planter’s specifications. The spacing between the two discs is crucial, and business cards can used to measure and set the spacing to form the perfect V-furrow. The openers can be adjusted by inserting or removing shims.

- Row unit gauge wheels: The gauge wheel is used to determine the depth of the row unit, and it is essential to ensure that these wheels do not throw dry soil over the newly planted seed. It is important that all the seed lands on the right moist soil. Check the wheels as well as the arms of the wheels to make sure they are not worn out, and make sure the adjustment is correct. It must seal tightly against your disc openers. If not, contact Ripper Tillage Equipment to resolve the issue quickly and effectively for you.

- Depth-adjustable arm: This arm is found on your gauge wheel and its purpose is to control depth. It also holds the gauge wheel in place.

- Closing wheel and spacing: After the seed is placed and firmly pressed into the seed furrow, the closing wheel all the way back on the row unit folds the loose soil over the seed furrow and press it firmly. It is important to make sure that the pressure, as well as the spacing on this wheel, is optimal for your soil condition. If it is not optimal, it can leave air pockets behind, or the seedbed is too tightly closed and pressed, making it difficult for the seedling to emerge through the soil. The closing system’s pressure must also be evenly distributed across the seed furrow. The process also preserves moisture for germination. If it does not work properly, it can cause emergence and yield problems. Make sure attention is paid to the unit.

- Meter drive system: This system mainly works mechanically with chains and gears. When the alignment of this action is not optimally set, it can cause problems with the seed placement. Components such as the chain and gears, tension adjuster and pulleys, and the hex bearings must be maintained and regularly inspected. It can cost you a lot of time in the field when you come to a standstill because you did not check it beforehand.

- Other servicing work: A planter has many moving parts to look after to ensure everything is lubricated. The tires must be checked regularly to ensure they are properly inflated. Neglecting to look after these things can hurt you during planting time in the field.

- Bar height: It is extremely important to make sure that your planter’s bar height matches the parallel unit on the row unit’s linkage so that the links are at the same height as the bar. You don’t want the row unit to hang on the bar, or maybe try to lift it too high. It can cause damage to the unit and other equipment on the planter.

- Level the planter: It is important to ensure that your planter runs level, and that your tool bar does not hang lower than the rest of the planter. This can cause the row cleaners to dig into the ground and the closing system at the back not to press firmly enough on the furrow.

- Evaluate your downforce setting: When you apply too much pressure on your downforce system, it can cause the outer walls of your seed furrow to compact. This makes it difficult for the closing system to work effectively. It can also cause you to work too deep in the ground with your seed and cause unnecessary wear on your planter units. When too little pressure is applied, there is a good chance that you will lose ground contact, and thus plant too shallow. This also affects your yield.

- Monitoring: Plant population, singulation, spacing, a good ride report, the operation of the closing device, soil moisture, and soil temperature should all be monitored from the cab while planting. The 20/20 screen from Precision Planting allows you to monitor and understand all these things so that you can make the right choice for the next hectare.

Do not let your planter hold you back, and more importantly, do not let uncertainty about components and adjustments to your planter hold you back. We at Ripper Tillage are here to walk the path with you.

Planter Maintenance Guide

Follow the link on the QR code to access the Planter Maintenance Guide.

Upgrade your planter

You do not necessarily have to replace your planter. Look for the following upgrades:

- vSet: A smaller and lighter seed meter with more accurate metering capability and easier maintenance.

- vDrive: Electrical motor that replaces mechanical drive, causes less wear, and can be individually controlled.

- Deltaforce: The equipment provides better control to the operator to ensure that the row units maintain constant 100% ground contact and provide a smoother ride, thereby improving yield and allowing each row unit to be controlled individually.

- Reveal row cleaners: These freely moving units are mounted on the planter bar and run independently of the row unit on their own pressure wheel to ensure that stubbles are properly swept out of the way, so that the seed can fall cleanly onto the seedbed without struggling with unnecessary moisture barriers.

Liquid and granular fertiliser equipment:

Martin Till fertiliser coulters:

Martin Till fertiliser coulters offer a variety of options for fertiliser addition to your soil. There is a single, as well as a double combination fertiliser applicator that is mounted in front of the row unit and works together with a freely moving row cleaner in front of the fertiliser coulter. It can apply fertiliser on one side or both sides of the seed about two inches (5 cm) away from the seed. This is a brilliant combination to add to your planter for liquid fertiliser, as it also serves as a row cleaner.

EM Flowsense:

This technology allows you to accurately determine the application rate of the fertiliser in each row individually, on your planter as well as the Side Dress Bar to make you aware of variation taking place and to give you confidence in your application rate.

V-Apply HD:

This technology allows you to place the right amount of liquid fertiliser at each plant. This ensures that your plant does not face starvation and you do not have to spend unnecessary money on excessive fertiliser application.

Clarity:

Standard blockage systems tell whether a product flows, but that is where it ends. CLARITY provides high-definition visibility in air seeders, planters, dry fertiliser applicators, and strip-till bars in real-time. The Clarity system displays and maps flow variability and product blockage size measures, row-by-row, on the 20|20 monitor in the cab.

Agxcel Schaffert Pop-up:

This system operates on its own. The operation and application of this product can be adjusted by the operator from the cab, from the system’s own application control. It is activated by a pressure switch activated by the parallel linkage units on the planter, which then causes the system to turn on and off as needed to ensure that there is no unnecessary application.

Keeton Firmers:

A seed firming device is a component that, as mentioned earlier in the planter maintenance guide, is used to press the seed into the seedbed, and ensure that air pockets are pressed out. Seed firmers are also used together with the Agxcel Schaffert system to ensure accurate application.

Deltaforce |

EM Flowsense |

Keeton Low Stick Firmer |

Agxcel Schaffert Pop-up System |

vApply HD |

vDrive-motor |

vSet-meter |

Visit the Ripper Tillage website at www.rippertillage.co.za. For more information, contact Werner Lubbe: (+27)62-240-9938 or Christine Bouwer: (+27)82-773-9297.