The right food at the right time in the right place makes children healthy, strong, useful citizens. The same goes for plants in your fields. Bogballe is the fertiliser spreader that ensures that no granule is wasted, but that each plant gets everything it needs to ensure you a good harvest.

Wynn Dedwith, CEO of Valtrac, tells. “My first introduction to Bogballe was around 1967. An old neighbour of ours bought a spreader and that is where I saw it for the first time.”

The brand name was not available in South Africa for a while, but Valtrac then decided to change it. A farmer can now easily get his hands on a Bogballe fertiliser spreader thanks to Valtrac’s nationwide network and excellent service that ensures you get the right equipment and unwavering service for your farming.

“We started importing the spreaders because Bogballe spreaders are different from any other spreader on the market,” says Wynn. “It is about the way in which the spreader’s discs turn.”

Most spreaders have discs that rotate away from each other, the left disc rotates counterclockwise and the right disc clockwise, but this is reversed on the Bogballe fertiliser spreader. The left disc rotates clockwise and the right one counterclockwise.

“The effect it gives is a unique spreading pattern on the outside,” Wynn says.

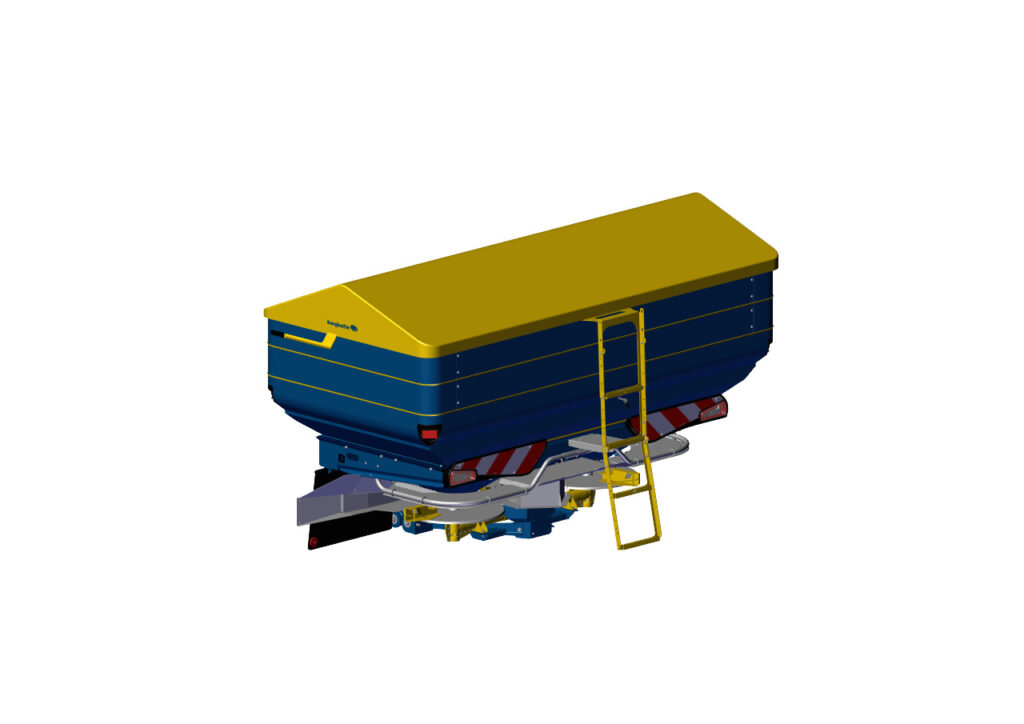

Bogballe’s spreaders are available in different sizes to fulfil every farmer’s need.

Wynn makes a comparison to someone sowing oats by hand to explain the pattern. “If you use your right hand, you sow from left to right, but with your left hand you sow from right to left. If you sow in this way, you cover the ground almost 180 degrees in front of you. This is exactly how the Bogballe spreaders work.

“Each disk spreads about 170 degrees behind the spreader, so if you have driven over your field once, it means that you have already spread twice because the pattern also spreads on top of each other. “If you then return and you drive on the side of your previous section, then you spread it again. The result is four layers of fertiliser that lie on top of each other.”

The advantage of this, of course, is that, if the tractor operator drives slightly crooked or misses part of the land for whatever reason with the second round, there will still be at least three layers of fertiliser across the land.

“Your spreading is so much more accurate, because if you miss once, then you are still sure there is fertiliser everywhere.”

Bogballe has thought of everything

Bogballe only offers benefits. For the only thing that could be a disadvantage, Bogbslle also had an answer: Wynn explained that the disadvantage of the rotational direction is that the edging on the fields is not as neat as an ordinary fertiliser spreader. “But Bogballe also made provision for that,” he points out. “In order not to scatter at the same 180 degrees on these parts, you simply pull a lever which then reverses the discs’ directions so that you can outline the land.

“Smaller models of the spreader have a lever, but on the larger models it is a button that you press in the cabin to make the direction switch.

“You can change the vanes on the discs to optimise them for both your fields edges and the rest inside.”

It works like this: the vanes have two sides. When the discs rotate in the original direction, the vanes are designed to give the best result for spread width. When the discs reverse for the outline, then it is the other side of the vanes’ turn. Therefore, it is designed in such a way as to offer the best outline.

“It is truly a unique spreader and as far as I know there is no other spreader in the world that works like this,” Wynn declares.

More reasons to choose Bogballe fertiliser spreaders

With fertiliser prices so high, farmers must have a fertiliser spreader that spreads accurately to get value from every grain of fertiliser. Wynn says: “When you fly in an airplane and you look down, you often see how fertiliser has been applied in rows. Every year the spots only get worse, and you see how there is a clear difference where fertiliser landed and where it did not. With a Bogballe spreader, fields do not look like that.

“At Valtrac, we can see that Bogballe fertiliser spreaders really work, even just measured by their popularity among our existing customers.

“We do contractor work where we spread for farmers, but often the farmer later buys a Bogballe fertiliser spreader himself because it is so effective.

The discs of the Bogballe fertiliser spreader rotate in the opposite direction compared to other spreaders on the market, for a more thorough spreading job.

“Bogballe uses a special paint that contributes to the longevity of each unit. The paint is formulated so that it does damage easily and there is no interaction between the paint and the ingredients in the fertiliser.

Each spreader is finished off by carefully rounding all sharp corners – this ensures that the paint adheres thoroughly and is not thinner in corners than on other parts of the implement.

It is of course important that your spreader is looked after if you want to get the most years out of it. Fertiliser can still form deposits on the spreader and affect its operation, but the solution is simple: you can wash the spreader thoroughly as soon as it has done its job and has to go back to the shed.

Bogball fertiliser spreaders are available in different bucket widths, from a narrower one that can work in an orchard and can hold 600 litres of fertiliser, to one that holds 6 000 litres. They are all modular so you can expand them by mounting more units on top.

Furthermore, Valtrac also has Bogballe spreaders ranging from the basic models to more advanced spreaders that are ISOBUS ready with section control and in-cab controls.

“It is very easy to calibrate the Bogballe,” Wynn says. “You just download a mobile phone application where you specify how much fertiliser of which type you want to spread and the application gives you the settings that must be made based on the fertiliser’s hardness, size, and so on. In the larger models that are ISOBUS equipped, the machine calibrates itself.”

The smaller models have a variety of accessories such as a scale and sieves that can help you find the size of your fertiliser – especially if it is a lesser-known brand name. “It just makes it easier for the farmers; they like it. It is not a case of driving up and down to calibrate the machine,” Wynn concludes.

Spread efficiently and precisely with a Bogballe fertiliser spreader. Contact Attie de Villiers on (+27)83-261-9863 or (+27)56-817-7308 or send an e-mail to attiedev@valtrac.co.za. Also visit the website www.valtrac.co.za.