Wood-Mizer’s edger and multirip range offer sawmillers affordable and scalable edger and multirip solutions that can grow, improve, and boost productivity, cutting accuracy and recovery levels for a competitive edge that builds bottom lines.

Edgers and multirips are designed to edge sideboards or slabs and flitches with wane and rip cants and blocks into boards consistently and efficiently over time within very tight tolerances. Any sawmill that wants to expand its output, cutting accuracy and recovery rates to get higher yields that adds to a sawmill’s bottom line, can use an edger or multirip to achieve these goals. Beyond the triple bottom line of better production, accuracy and recovery, there are several other benefits that sawmillers also get when they choose an edger or multirip from Wood-Mizer.

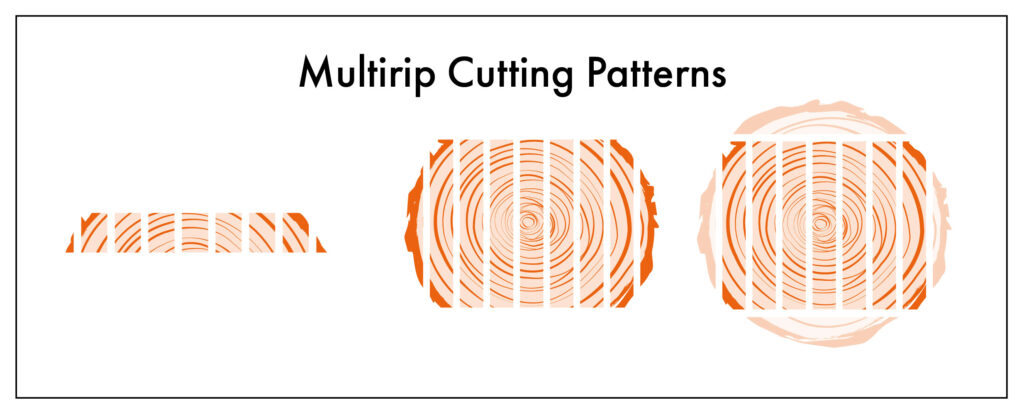

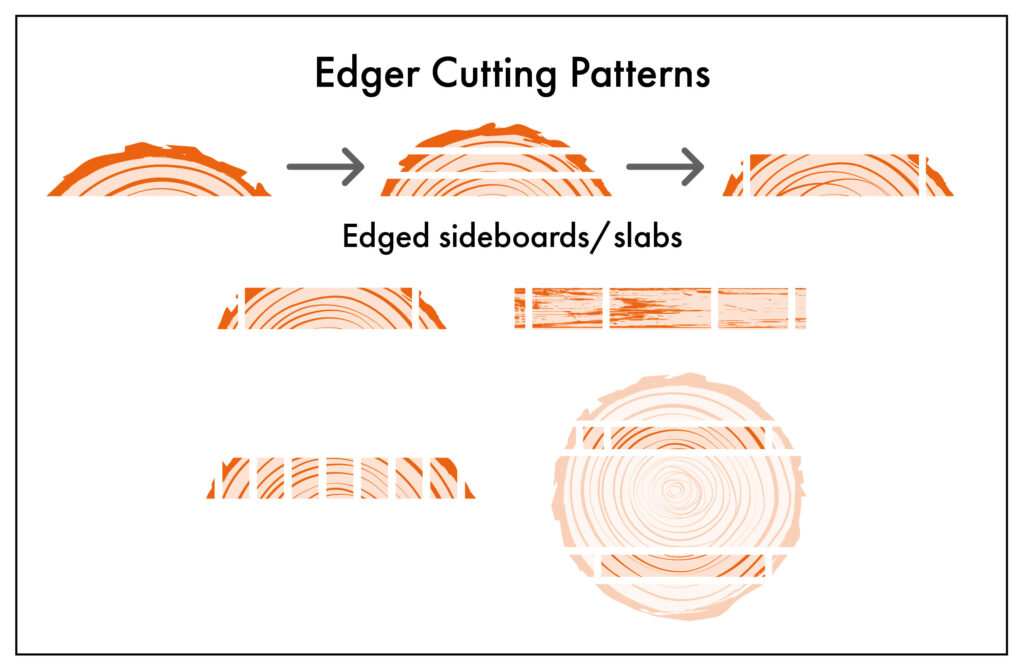

The cutting patterns that produced by edgers and multirips.

Wood-Mizer’s Edger Multirip range

The range offers a full line-up of entry-level, light and heavy industrial single or double arbour edger and multirip solutions that can work as standalone units or slot into existing lines. The focus of the range is to make affordable, scalable, and modular edging and multirip solutions available to sawmillers that can fit into the budgets and production targets of sawmills irrespective of their size.

This gives start-up and industrial producers equal access to one range that includes entry-level and high-production capacity machines with the ability to either add standalone units to existing lines or design and build new lines with edging and multirip solutions from Wood-Mizer part of it.

The scalability of the range adds further choice with entry-level edgers and multirips offering basic capabilities with more power, output capabilities and options giving, adding additional punch for producers needing higher capacity edgers or multirips.

Investing in a product range supported globally by a professional after-sales service network for a sawmill’s lifespan makes partnering with Wood-Mizer an even bigger win for sawmillers.

Wood-Mizer’s EG300 is an affordable and highly productive multirip edger combination that is used to maximize recovery from each board and boost sawmill productivity.

Edgers and Multirips – Adding value to a sawmill?

There is a lot of overlap between the design, function and benefits that edgers and multirips offer. Both machining platforms have robustly designed frames that give the torsional rigidity needed to support the arbours and circular blades that cut accurately sized timber consistently at high speed and volumes over time. Both are used during the secondary breakdown phase of the sawmilling process to break or cut the components that exit the primary breakdown stage down further.

Edgers edge, trim or square sideboards or slabs and flitches with wane from the primary breakdown phase into a uniform-size product. Multirips rip cants and blocks exiting the primary breakdown phase into boards. Both also offer specific benefits that allow sawmills to improve efficiencies, increase productivity, boost recovery and bolster the safety levels of a mill.

The EG800 manual board edger is a robust edging and multirip solution for small to medium sized sawmills. In an edger configuration, it can edge boards up to 40mm and as a multirip rip blocks or cants up to 120mm thick.

Increased efficiency:

A board edger increases the efficiency of the process used by a sawmill to trim and square sideboards/slabs and flitches with wane into uniform sizes. Edging helps sawmillers process lumber more quickly and efficiently. By trimming and squaring rough boards, the machine creates straighter, more uniform boards, which can be processed more efficiently. Sideboards that formerly went to waste but are now sawn into boards with less waste boost profits.

Adding a multirip to a sawmill’s line-up boosts efficiency by simplifying the log breakdown process. It harnesses the speed and accuracy of a band mill to break logs into cants, with the strength, simplicity, and accuracy of a multirip, then used to saw the cants or blocks into finished boards.

A multirip also has fewer moving parts to maintain than a multi-head band resaw that does a similar job. Fewer stoppages and less maintenance are money in the pocket, increasing efficiency and boosting productivity.

Improved quality:

The consistent sizing that an edger delivers improves the quality of the sawn produced with consistently sized, straight and uniformly sized build the bottom line. The accuracy that a multirip delivers reduces the wet target size of a sawmill with reduced within-board sawing variation, less waste and higher yields from each board growing profits. Reject boards caused by sawing inaccuracy also eat into profits – boards that are not the right size will not sell. Well-set-up multirips always cut straight. Straight boards sell well.

Reduced waste:

Using an edger to trim and square rough boards reduces waste and increases yield. An edger can easily produce sawn product from sideboards or slabs that are often left as waste, and more sawn product and less waste build profits. The accuracy that a multirip provides slashes the within-board size variation with less waste and higher yields, growing profits.

Versatility:

Using an edger and multirip allows sawmillers to produce more lumber sizes and timber products faster. More sawn product produced faster from a variety of log shapes builds sales.

Increased safety and reduced labour costs:

Using a board edger can help to improve safety in the sawmill by reducing the need for manual trimming and squaring of boards. This can help to reduce the risk of accidents and injuries and makes the sawmill a safer place to work in. Introducing a multirip can reduce the labour bill with fewer workers needed to operate fewer machines and handle a simpler material flow through the mill.

Less resharpening

An edger and multirip can work across shifts without blade changes. Although circular sawblades cost more than bandsaw blades, they require less resharpening and fewer delays to change blades, with this reducing the workload to resharpen blades with more uptime in a shift producing more boards.

Reduce maintenance costs

Using edgers and multirips simplifies the operation with fewer machines that must be maintained, slashing running costs and higher volumes adding to the bottom line.

Improved material and waste handling

The simpler material flow that an edger and multirip offer streamlines material handling and waste removal processes to boost efficiency and slash costs.

- The MR6000 Multirip / Gangsaw is Wood-mizer’s flagship multirip. Built for the most demanding industrial applications, it offers various feed options linked to the latest scanning and optimizing systems to provide for industry-leading yield results.

- With up to 4 moveable blades and a picker finger outfeed system, the EA3000 optimizing edger uses optical scanning technology to achieve high-precision edging results that minimizes waste and provide the yields needed by sawmills to generate industry-leading returns.

Manufacturing quality

The guideline that shapes Wood-Mizer’s edger multirip range is to produce machines that deliver the cutting accuracy and size tolerances needed by timber producers that invest in the range. Properly aligning the feed rollers and arbours is critical in achieving the required cut tolerances. If the required alignment standards are not met, it can cause a range of problems other than not cutting straight.

Bearings will fail faster, and blades will become blunt sooner because they do not run true in the cut. With more strain on all the parts, breakdowns and upkeep will increase. To overcome this, some companies use costly equipment to get the alignment needed resulting in an excellent end-product but at a very high price.

Others cut costs by fabricating machine frames from tube steel and using cheap bearings. Such frames don’t have the torsional strength to withstand the forces experienced by these machines, so the system’s alignment degrades over time. Some systems integrate re-alignment tools into the bearing seats. While this may allow very skilled artisans to align a machine properly, it can be done wrong by an inexperienced technician. The result of improper alignment is that the machine will struggle to feed, blades will dish, power consumption will go up and bearing life suffers.

Wood-Mizer uses a strong and rigid frame for its edger and multirip range made from thick plate. The components are pre-cut on CNC systems and then webbed and welded together for a rigid structure with exceptional alignment. Bearings for both rollers and arbours are bolted into position with no need for further alignment procedures, and this eliminates any guesswork when replacing components in the field.

The result is consistent accuracy without fail.

Wood-Mizer’s Edger Multirip range provides for the following options:

- EG100: Twin-blade manual board edger

- EG250: Dependable twin-blade board edger

- EG300: Multirip Board edger

- MR200: EG800 Edger Multirip

- MR3000: Multirip Gangsaw

- MR6000: Multirip Gangsaw

- EA1000: Optimizing Edger

- EA3000: Optimizing Edger

Visit www.woodmizer.com for a full rundown of our edger multirip range.